The DTF Gangsheet Builder is revolutionizing the landscape of custom transfer printing, providing a game-changing solution for those involved in direct-to-film (DTF) printing. This innovative tool allows users to maximize the potential of their printing processes by enabling multiple designs to be printed on a single gang sheet, significantly optimizing resource use. Businesses are increasingly discovering the benefits of this printing process optimization, as it not only reduces costs but also enhances efficiency. As the demand for vibrant, high-quality prints in the custom apparel industry rises, the DTF Gangsheet Builder stands out as a vital asset for both small entrepreneurs and large printing operations. By embracing this technology, creators can elevate their printing capabilities while ensuring they meet the fast-paced needs of their customers.

In the evolving world of apparel printing, the DTF Gangsheet Builder emerges as a pivotal innovation in the realm of direct-to-film techniques. This sophisticated method of custom transfer printing streamlines the process by allowing various designs to coalesce onto a single sheet, commonly referred to as a gang sheet. As businesses strive to enhance their production efficiency, tools like the Gangsheet Builder facilitate significant improvements in workflow and cost management. By integrating cutting-edge printing technology that optimally uses materials, companies can deliver high-quality prints that appeal to a market that increasingly values customization. This shift towards modern printing processes emphasizes not only efficiency and quality but also the need for creativity in every design initiative.

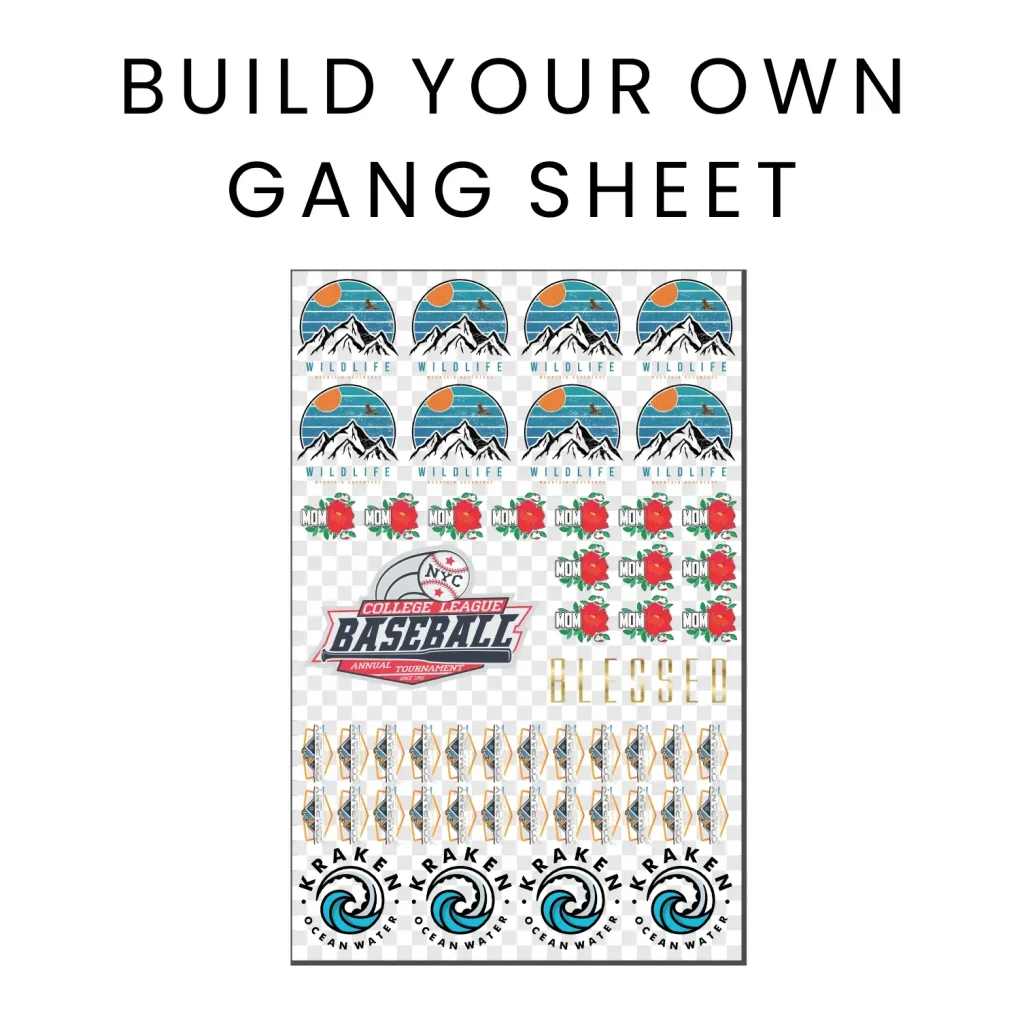

Revolutionizing Your Workflow with DTF Printing

The introduction of Direct-to-Film (DTF) printing technology is revolutionizing the way businesses approach the custom printing process. Unlike traditional methods, DTF printing utilizes heat transfers and specialized inks to deliver vibrant, high-quality prints on various materials. This innovative technique not only enhances the aesthetics of printed apparel and accessories but also allows for a smoother texture that retains the original fabric feel. As a result, creators can produce garments that not only look amazing but are also comfortable to wear, catering to a broader audience.

Moreover, the DTF printing process is streamlined, making it attractive for both small businesses and large-scale operations. With the ability to handle multiple designs simultaneously, companies can respond quickly to changing market demands without sacrificing quality. The increased efficiency minimizes waste and optimizes resources, enabling businesses to scale their printing capabilities effectively. As such, adopting DTF printing can be a game-changer for startups and established enterprises alike, ensuring they remain competitive in an ever-evolving landscape.

Maximizing Efficiency with the DTF Gangsheet Builder

One of the most remarkable features of DTF printing is the DTF Gangsheet Builder, which has become essential for optimizing efficiency. This tool allows users to assemble multiple graphics onto a single sheet before printing, thereby maximizing material use and reducing operational costs. By minimizing film wastage, businesses can significantly decrease the cost per item, which is crucial in a competitive market where margins are tight. Furthermore, this efficiency translates into higher production rates, allowing companies to fulfill larger orders more swiftly.

The DTF Gangsheet Builder also helps simplify the design process, eliminating the need for time-consuming manual adjustments. This software not only ensures correct alignment of designs on the gang sheet but also mitigates potential misprints. As a result, businesses can focus more on creativity and less on logistics. Leveraging the DTF Gangsheet Builder is thus a key step toward achieving greater productivity and efficiency in the printing workflow, setting companies up for success in the demanding world of custom apparel.

Exploring the Benefits of Custom Transfer Printing

As consumer demand for unique apparel continues to rise, the benefits of custom transfer printing through DTF technology are becoming increasingly apparent. Custom transfer printing allows for a personal touch on products, enabling businesses to cater to niche markets that appreciate individuality. Not only does this method appeal to customers looking for personalized gifts or unique products, but it also fosters brand loyalty as consumers feel more connected to brands that offer customization options.

Additionally, custom transfer printing reduces the barriers to entry for small businesses and independent creators looking to enter the market. With user-friendly software and tools like the DTF Gangsheet Builder enhancing the printing process, even individuals with limited technical skills can produce high-quality prints. This democratization of printing opens up new opportunities for entrepreneurs and artists, empowering them to launch products that reflect their vision and meet consumer demands.

Ensuring Quality and Consistency in Print Production

Quality assurance is a cornerstone of successful custom printing, and DTF printing stands out for its ability to deliver consistently vibrant and durable designs. Unlike traditional printing methods, DTF technology employs advanced ink formulations that bind effectively with fabric fibers during the heat transfer process. This results in prints that maintain their color vibrancy and resist fading over time, even after multiple washes. Clients can trust that their orders will meet high-quality standards, leading to increased satisfaction and repeat business.

Moreover, the DTF Gangsheet Builder further enhances quality control by enabling a more streamlined printing process. By using gang sheets, printers can ensure that all designs remain aligned during the printing operation, reducing the likelihood of misprints or inconsistencies. This meticulous attention to detail not only improves the final product but also positions businesses as reliable sources for custom apparel, ultimately fostering long-term relationships with customers.

The Impact of Recent Developments in DTF Technology

The DTF printing industry is experiencing rapid advancements that are expanding its capabilities and enhancing service quality. Notable developments, such as improvements in printer technology and software, have made it easier for companies to meet growing consumer demands swiftly. For instance, larger format DTF printers have emerged, allowing businesses to produce bulk orders with greater speed and efficiency. This evolution not only elevates the standard of printing but also opens doors for new applications, such as printing on larger fabrics or diverse materials.

Additionally, innovations in DTF gang sheet creation mean that businesses now have access to tools that prioritize ease of use without sacrificing quality. Platforms offering intuitive interfaces and step-by-step guidance allow users to produce complex designs with minimal effort. This level of accessibility encourages more entrepreneurs to explore DTF printing as a viable option for their businesses, contributing to the overall growth of the market and meeting the increasing demand for high-quality, custom printed goods.

Future Trends in DTF Printing and Custom Transfer Solutions

Looking forward, the future of DTF printing and custom transfer solutions appears bright as technology continues to evolve. With ongoing improvements in ink chemistry, film materials, and printing equipment, the quality and efficiency of DTF printing are expected to rise even further. Innovations such as water-based inks and eco-friendly films are anticipated to hit the market, aligning with the growing sustainability demands of consumers. This trend towards greener printing solutions could significantly influence how businesses operate, requiring them to adapt their practices to remain relevant.

Moreover, the increasing integration of digital printing systems with automation technologies will likely enhance workflow efficiencies across the industry. Companies that harness artificial intelligence and machine learning to optimize printing processes are poised to gain a competitive edge. As the DTF market matures, businesses that invest in cutting-edge technologies, such as the DTF Gangsheet Builder, will be well-positioned to capture expanding opportunities and provide unparalleled service to their customers.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a specialized tool that optimizes the DTF printing process by allowing users to arrange multiple designs on a single gang sheet. This enhances DTF printing by maximizing material use, reducing waste, and lowering costs while maintaining high-quality prints.

How does the DTF Gangsheet Builder improve cost-efficiency in custom transfer printing?

By using gang sheets to print multiple designs at once, the DTF Gangsheet Builder significantly cuts down costs per item. This is achieved by optimizing the use of direct-to-film materials and minimizing material waste during the custom transfer printing process.

What are the key benefits of using gang sheets with the DTF printing technique?

The key benefits of using gang sheets in DTF printing include cost savings, reduced production time, high-quality print outcomes, ease of use, and versatility across various substrates. This makes the DTF Gangsheet Builder an essential asset for businesses engaged in custom transfer printing.

Can the DTF Gangsheet Builder handle different fabric types for direct-to-film printing?

Yes, the DTF Gangsheet Builder is designed to accommodate various fabric types, making it versatile for printing on t-shirts, bags, and other materials. This flexibility is one of the many advantages of integrating DTF printing with gang sheets.

How does the DTF Gangsheet Builder support efficiency in print production?

The DTF Gangsheet Builder supports efficiency by allowing the simultaneous printing of multiple designs, which speeds up production times and reduces the risk of misalignment. This optimization in the DTF printing process ensures that resources are used effectively.

What role does DTF printing play in the rise of custom transfer printing?

DTF printing has revolutionized custom transfer printing by providing high-quality, vibrant prints with faster production capabilities. The DTF Gangsheet Builder enhances this process, allowing businesses to efficiently create custom designs, thus meeting the increasing consumer demand for personalized products.

| Key Point | Details |

|---|---|

| DTF Printing | Modern technique using specialized ink and heat transfers for vibrant prints on fabric. |

| Gang Sheets | Combines multiple designs on a single sheet for efficient printing and cost reduction. |

| Cost-Efficiency | Reduces cost per item by maximizing material use through gang sheets. |

| Time-Saving | Allows multiple designs to be printed simultaneously, speeding up production times. |

| Quality Assurance | Preserves vibrant colors and fidelity by reducing misalignment risks during printing. |

| Ease of Use | User-friendly interfaces make it accessible for beginners in printing. |

| Versatility | Ability to print on various materials, expanding business opportunities. |

Summary

The DTF Gangsheet Builder is revolutionizing the printing landscape by streamlining how businesses approach direct-to-film printing. This innovative tool not only optimizes efficiency and cost-effectiveness but also ensures high-quality outputs that meet the demands of today’s custom apparel market. By leveraging features like gang sheets, users can simultaneously print multiple designs, significantly enhancing productivity. As the DTF printing sector continues to grow, adopting the DTF Gangsheet Builder proves to be an essential step for businesses looking to stay competitive while improving their workflows and customer satisfaction.