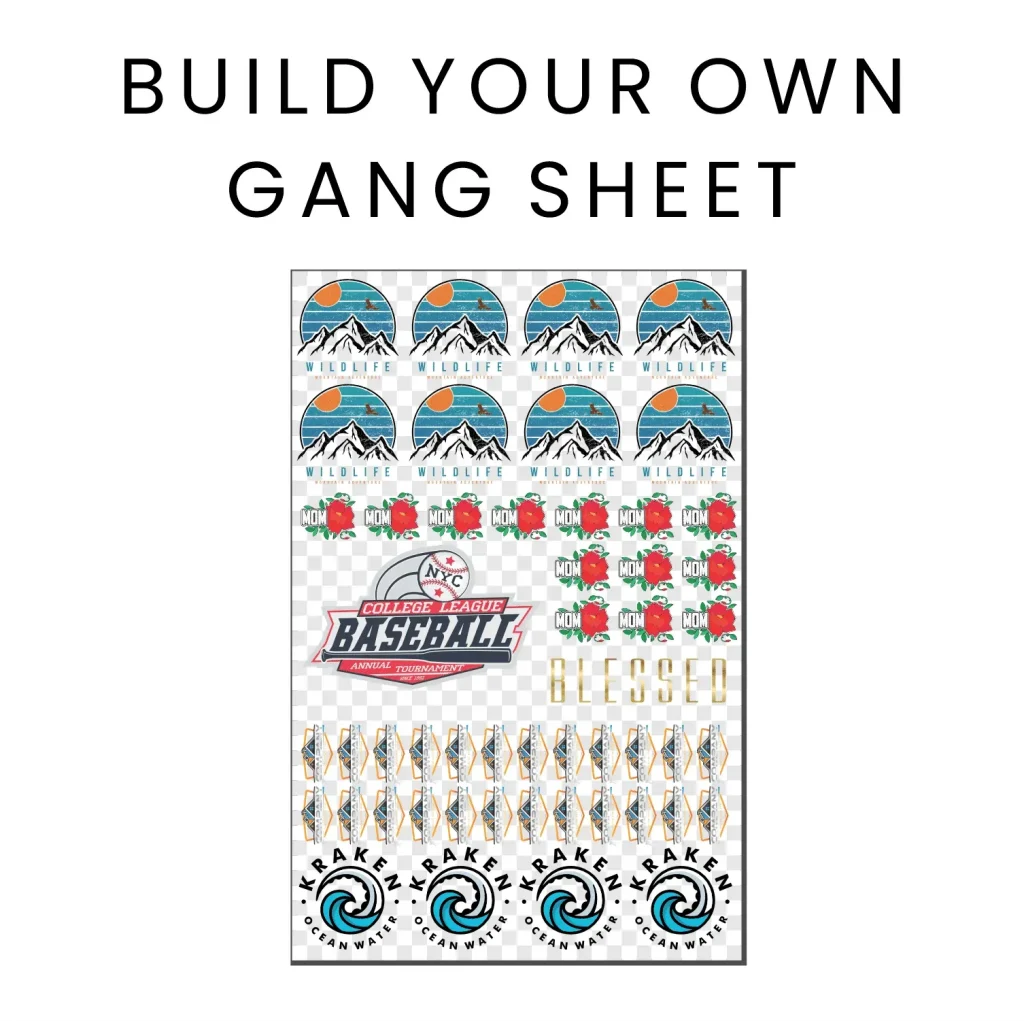

The DTF Gangsheet Builder is a revolutionary tool for those diving into the vibrant world of Direct to Film (DTF) printing. By mastering this innovative software, users can optimize their gang sheet layout to enhance both productivity and print quality. Whether you aim for intricate designs or straightforward patterns, utilizing effective DTF printing tips can significantly streamline your production process. In this guide, we will delve into essential techniques, including selecting the right DTF design software and optimizing designs for DTF applications, ensuring you get the most out of your printing endeavors. Unlocking the secrets of the DTF Gangsheet Builder will not only elevate your printing skills but also give you a competitive edge in this ever-expanding market.

When exploring the realm of Direct to Film printing, the ability to efficiently create and manage gang sheets is crucial for success. The Gangsheet Creator serves as an essential resource, allowing users to maximize their design layouts while ensuring clarity and precision in film transfer printing. Accessing effective DTF printing strategies and utilizing software tailored for DTF applications empowers designers to craft eye-catching prints. Additionally, learning how to layout designs optimally will reduce material waste and enhance the overall printing experience. As the industry grows, adapting to these practices becomes necessary for those looking to excel in the vibrant DTF landscape.

Harnessing the Power of DTF Design Software

In the world of DTF printing, utilizing the right design software is paramount to achieving exceptional results. Programs like Adobe Illustrator and CorelDRAW offer unique functionalities tailored for creating intricate gang sheet layouts. Familiarizing yourself with these tools will provide you a competitive edge, enabling you to manipulate and optimize designs effectively. By mastering these design environments, you can take full advantage of their features, which include vector manipulation and color management, essential for preparing your prints.

Moreover, efficient use of DTF design software also allows for better scalability of your print projects. As you become adept at utilizing templates and design presets, you’ll streamline your workflow, ultimately reducing production time. Incorporating these software programs into your process not only enhances your creativity but also ensures that you can deliver high-quality prints consistently, bolstering your reputation as a skilled DTF printer.

Optimizing Your Gang Sheet Layout for Maximum Output

Creating the perfect gang sheet layout is crucial for maximizing efficiency in DTF printing. A well-structured layout allows printers to fit as many designs as possible on a single sheet, which helps reduce waste and cut costs. To optimize your gang sheet layout, consider using grid systems and layout guides to ensure that each element is aligned and spaced correctly. This attention to detail not only enhances the visual appeal of your designs but also minimizes the risk of alignment errors during the printing process.

Additionally, implementing effective spacing techniques can help you achieve a balanced design. Group similar items together while ensuring sufficient margin area to avoid print bleed. The more efficient your gang sheet layout, the better you can optimize your printing process for both speed and resource management. Adopting these practices will allow you to produce more designs using less material, making your DTF printing operations more sustainable and profitable.

The Importance of Quality Films and Inks in DTF Printing

When it comes to DTF printing, selecting the right films and inks is fundamental to achieving vibrant and durable prints. High-quality DTF films should be compatible with your specific printer and fabric types to ensure excellent adhesion and clarity. Lower quality films may lead to poor print outcomes, tarnishing your reputation and affecting customer satisfaction. Thus, always choose films that are specifically designed to work optimally with your equipment.

Inks, too, play a vital role in the quality of your prints. Using compatible, high-quality inks will not only enhance the vibrancy of your designs but also ensure that the colors remain accurate during washing and wear. It’s essential to adhere to manufacturers’ specifications to avoid compatibility issues that can compromise the integrity of your prints. Investing in the right materials serves as a foundation for any successful DTF printing operation.

Conducting Effective Test Prints to Validate Designs

Before committing to full production runs, conducting test prints is a crucial step in the DTF printing process. Test prints allow you to verify the color accuracy, alignment, and overall design quality without risking significant material costs. By running small-scale tests, you can pinpoint any necessary adjustments in your design file or printing settings to achieve the desired outcome. This practice not only saves time but also enhances the fidelity of your final product.

Moreover, executing test prints cultivates a preventive approach to troubleshooting. It enables you to identify issues such as misalignment or color discrepancies early on, preventing costly reprints later in the process. Adopting a habit of performing test prints ensures that you maintain high standards in print quality and customer satisfaction, making it a best practice in the DTF printing industry.

Post-Processing Techniques for Durable DTF Prints

After successfully printing your designs using the DTF Gangsheet Builder, focus shifts to post-processing techniques, which are crucial for ensuring the longevity and durability of your prints. One of the most effective methods is heat pressing, which helps in curing the prints properly. Following the recommended time and temperature settings for the specific inks you’re using can make the difference between a durable design and one that fades or wears quickly. Proper curing ensures that your colors remain vibrant and that the designs adhere well to the fabric.

Apart from heat pressing, inspecting each print for quality before delivery is essential. Small imperfections can often escape notice in bulk production, but a thorough inspection can maintain your quality standards. Additionally, considering the use of water-resistant coatings adds an extra layer of protection, especially for items frequently washed. Incorporating these post-processing techniques will not only enhance the quality of your prints but also increase customer trust and satisfaction.

Continuous Learning and Adaptation in DTF Printing

As the DTF printing landscape evolves, staying informed and adaptable is vital for anyone looking to excel in the industry. Participating in DTF communities, reading industry publications, and attending relevant workshops can provide invaluable insights into emerging trends and technologies. This dedication to continuous learning enhances your skills and understanding of best practices, positioning you to leverage new opportunities as they arise.

Furthermore, sharing your experiences and knowledge with others can foster growth and innovation within the DTF printing community. By remaining open to new techniques and collaborative projects, you can push the boundaries of what your DTF prints can achieve. This mindset not only enhances your own business but also contributes to the growth and advancement of the entire industry, making you a leader in the field.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing efficiency?

The DTF Gangsheet Builder is a specialized tool used in Direct to Film (DTF) printing for creating gang sheets—arrangements of multiple designs on a single film sheet. By using this builder, you can optimize your designs for DTF printing by maximizing film usage, reducing waste, and enhancing overall production efficiency.

What are some important DTF printing tips to consider when using the DTF Gangsheet Builder?

When using the DTF Gangsheet Builder, crucial tips include understanding your DTF design software, optimizing gang sheet layouts, selecting high-quality films and inks, conducting test prints, and following post-processing techniques to ensure durability and vibrant prints.

How can I optimize my gang sheet layout in the DTF Gangsheet Builder?

To optimize your gang sheet layout in the DTF Gangsheet Builder, minimize the space between designs, use grid systems for alignment, and ensure that your designs fit within the print area effectively. This helps in maximizing output and lowering material costs.

What DTF design software is best for creating gang sheets?

Popular DTF design software for creating effective gang sheets includes Adobe Illustrator and CorelDRAW. These programs facilitate precise design arrangements and offer features that support gang sheet layouts for efficient DTF printing.

Why is it important to select the right film and inks for DTF printing with gang sheets?

Selecting the right film and inks for DTF printing is vital because the compatibility of these materials directly affects print quality. High-quality films ensure good adhesion to fabrics, while compatible inks enhance vibrancy and durability, resulting in better overall prints.

What post-processing techniques are recommended after using the DTF Gangsheet Builder?

After using the DTF Gangsheet Builder, recommended post-processing techniques include heat pressing your designs according to ink specifications and applying water-resistant coatings for additional protection. Proper curing will secure the print’s quality and longevity.

| Key Point | Description |

|---|---|

| Understanding the Design Software | Familiarize yourself with design tools like Adobe Illustrator and CorelDRAW to create efficient gang sheet layouts. |

| Optimal Layout for Printing | Minimize space, use grid systems to align designs accurately, and maximize the number of prints per sheet. |

| Select the Right Film and Inks | Choose high-quality films and compatible inks that ensure vibrant colors and adherence to fabrics. |

| Use Test Prints | Perform test prints to check color accuracy and make adjustments before large runs. |

| Post-Processing Techniques | Properly cure prints using heat pressing and inspect for quality to ensure durability and longevity. |

Summary

DTF Gangsheet Builder is a crucial tool for anyone looking to excel in DTF printing. By understanding design software, optimizing layouts, selecting quality materials, performing test prints, and implementing effective post-processing techniques, you can elevate the quality and efficiency of your printing projects. Embracing these strategies not only enhances your production workflow but also positions you as a knowledgeable player in the dynamic realm of DTF printing. Continually learning and adapting is key to mastering this art, ensuring your success in the competitive landscape.