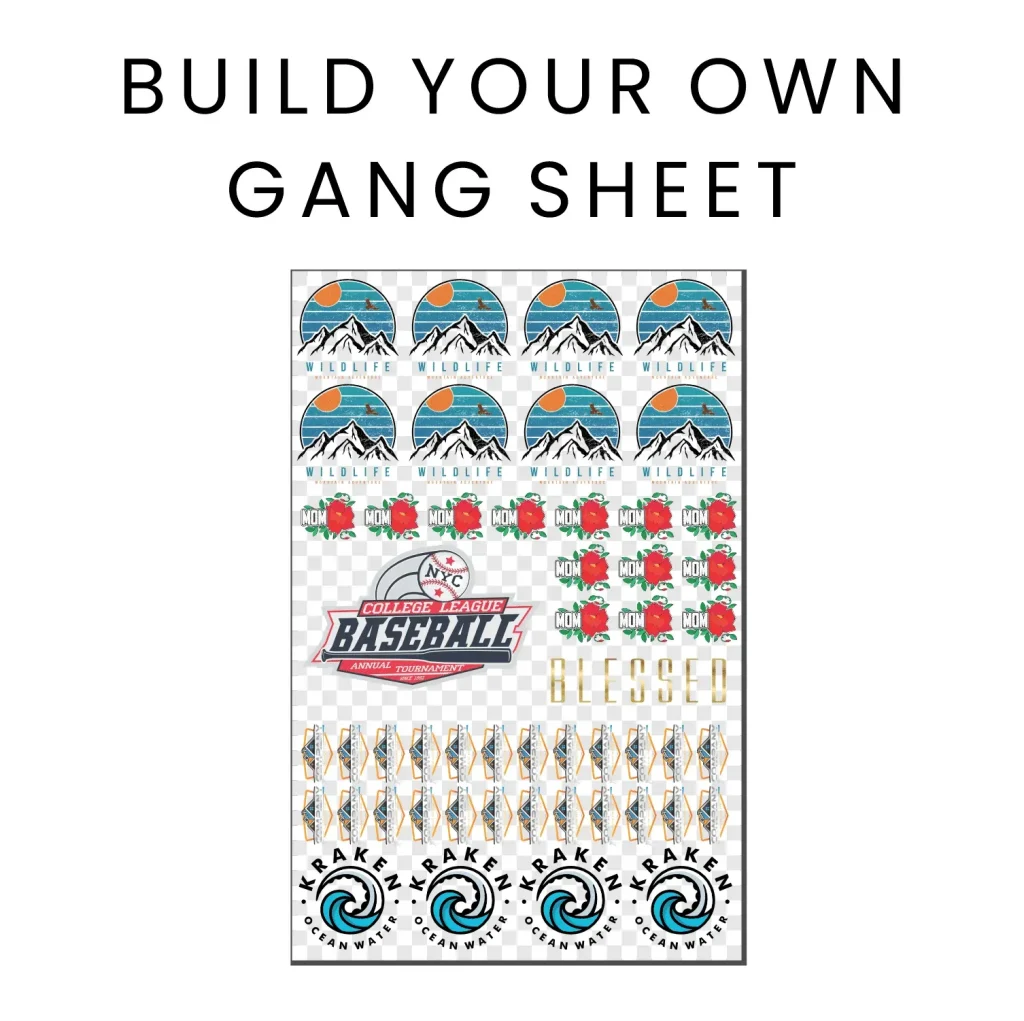

In the rapidly evolving landscape of print shop technology, the **DTF gangsheet builder** stands out as an essential tool for optimizing printing efficiency and enhancing custom apparel printing capabilities. This innovative solution enables print shops to streamline their processes by efficiently arranging multiple designs onto a singular sheet, significantly minimizing material waste. By leveraging DTF printing techniques, businesses can not only improve cost-effectiveness but also deliver high-quality results that meet the ever-increasing demands of customers. As the need for intricate designs and quick turnaround times intensifies, the DTF gangsheet builder becomes a game-changer for print operations, ensuring they remain competitive in today’s fast-paced market. Adopting this technology is no longer a luxury but a necessity for print shops aiming to thrive.

When discussing tools that revolutionize printing workflows, the term **gangsheet optimization** often comes into play, synonymous with the efficiency gains realized through such advancements. Print shops can embrace the benefits of Direct-to-Film (DTF) setup methodologies, streamlining production while maximizing the use of materials. This strategic approach to custom apparel production empowers businesses to cater to diverse order requirements swiftly and effectively. In essence, employing a gangsheet builder not only enhances flexibility but aligns perfectly with the shifts towards sustainable printing practices. By adopting these modern tools, print shops can significantly enhance operational capabilities, paving the way for a successful future.

Understanding DTF Printing: A Game Changer for Print Shops

Direct-to-Film (DTF) printing is rapidly transforming the landscape of custom apparel production. Unlike traditional methods, DTF printing allows for greater flexibility and creativity, enabling print shops to produce high-quality designs efficiently. With its unique process, DTF printing uses heat transfer film to apply vibrant colors directly to fabrics, which results in stunning visuals and durability that customers crave. This technology not only enhances the aesthetic appeal but also meets the growing demand for intricate designs in the apparel sector.

Moreover, DTF printing optimally integrates with the DTF gangsheet builder, further enhancing this innovative process. This builder facilitates the arrangement of multiple prints on a single film, which significantly reduces material waste and increases productivity. By utilizing the right technology, print shops can better respond to customer demands, yielding high-quality finishes that cater to both large and small custom orders.

Maximizing Printing Efficiency with DTF Gangsheet Builders

The integration of a DTF gangsheet builder into print shop technology can dramatically maximize printing efficiency. By organizing various designs onto a single sheet, this tool helps printers to execute multiple orders simultaneously, cutting down the overall time spent on each print run. This optimized approach not only facilitates a smoother workflow but also empowers businesses to increase output without sacrificing quality, ensuring they keep pace with market demands.

In essence, maximizing printing efficiency through a gangsheet builder not only reduces downtime during the production process but also lowers costs associated with material waste. Print shops are then able to allocate resources more effectively and take on larger volumes of work, improving their overall profitability. As the demand for quick turnaround times rises, implementing this technology becomes crucial for maintaining relevance and competitiveness in the custom apparel industry.

The Role of Gangsheet Optimization in Custom Apparel Printing

Gangsheet optimization plays a pivotal role in enhancing the efficiency of custom apparel printing. By maximizing each sheet’s area, print shops can fit multiple designs onto a single layout, allowing for better resource utilization. This approach not only reduces material costs but also minimizes setup and production times, as only one film needs to be processed for multiple items.

Additionally, the careful placement of designs facilitated by gangsheet optimization ensures that the finished products maintain a high quality standard. Each print job is more precisely executed, aligning patterns perfectly and meeting customer expectations for excellence. Therefore, employing a DTF gangsheet builder fundamentally transforms how print shops operate, leading to superior results that resonate with clients.

Flexibility in Designs: Meeting Customer Demands

In today’s fast-paced market, flexibility in design options significantly influences customer satisfaction. Consumers increasingly seek unique products that resonate with their personal style and brand identity. A DTF gangsheet builder enables print shops to cater to diverse and often fluctuating customer demands by allowing a variety of designs to be printed in smaller quantities without extensive downtime.

This flexibility not only attracts new clients but also fosters loyalty among existing customers who appreciate the ability to customize their orders. By responding to specific requests through efficient gangsheet layouts, print shops can effectively build stronger client relationships and enhance their reputation in the custom apparel industry, ensuring steady business growth.

High Quality and Consistency: Ensuring Customer Satisfaction

Quality and consistency are paramount in the custom apparel printing business. Investing in a DTF gangsheet builder aids in achieving these critical benchmarks by ensuring that designs are printed accurately and uniformly across multiple items. This technological advancement minimizes the chances of errors that can occur with manual setups, thereby enhancing the overall product quality.

Furthermore, consistent high-quality output not only satisfies customers but also promotes repeat business and referrals. Print shops that prioritize quality through the use of DTF technology can position themselves as leaders within their community, cultivating a loyal customer base that appreciates the value of expertly crafted apparel.

Technological Advancements in Print Shop Efficiency

The continuous evolution of print shop technology has ushered in a new era of efficiency, particularly with the advent of DTF printing and gangsheet builders. Modern software solutions simplify the design process, enabling operators to create optimized layouts with relative ease. As these tools become more sophisticated, they allow even those with minimal training to produce high-quality prints.

Additionally, advancements in DTF printing technology facilitate seamless integration into existing workflows, which is essential for maintaining productivity. Print shops that embrace these technological advancements are not only better positioned to meet client needs but are also likely to outperform competitors who resist change. Keeping pace with technology ultimately leads to sustainable growth and profitability.

Frequently Asked Questions

What is a DTF gangsheet builder and why is it essential for print shops?

A DTF gangsheet builder is a tool used in Direct-to-Film (DTF) printing that optimizes the arrangement of multiple designs on a single sheet. It is essential for print shops as it enhances material efficiency, reduces waste, and streamlines the printing process, thereby improving productivity and cost-effectiveness.

How does a DTF gangsheet builder improve printing efficiency?

A DTF gangsheet builder improves printing efficiency by allowing multiple designs to be printed in a single run, significantly reducing setup time. This means print shops can complete jobs faster, meet tight deadlines, and take on more projects, ultimately enhancing workflow efficiency.

What are the benefits of using a DTF gangsheet builder in custom apparel printing?

Using a DTF gangsheet builder in custom apparel printing leads to improved material use, time savings, and high-quality outputs. It allows print shops to serve diverse client needs flexibly, ensuring that all apparel designs are produced cost-effectively and with minimal waste.

Can a DTF gangsheet builder help in achieving better quality and consistency in prints?

Yes, a DTF gangsheet builder contributes to better quality and consistency in prints by ensuring precise design placements. Advanced quality control features reduce errors, leading to visually appealing products and increased customer satisfaction, which is key for repeat business.

How does the use of DTF gangsheet builders address market demand fluctuations in print shops?

DTF gangsheet builders address market demand fluctuations by offering print shops the flexibility to produce various designs in small quantities without extensive reconfiguration. This adaptability allows shops to respond quickly to changing customer preferences and seasonal trends.

What technological advancements are associated with DTF gangsheet builders?

Technological advancements in DTF gangsheet builders include user-friendly software with enhanced functionalities that simplify the design process. These innovations allow printing operators to easily integrate the builders into their workflows, facilitating faster and more accurate print production.

| Key Points | Description |

|---|---|

| DTF Printing | A method that allows efficient production of custom designs on apparel. |

| DTF Gangsheet Builder | Essential tool for optimizing print layouts and enhancing productivity. |

| Material Efficiency | Reduces waste by optimizing design placement, saving costs and promoting sustainability. |

| Time Savings | Streamlines printing process, allowing for faster job completion and improved workflow. |

| Flexibility | Enables production of diverse custom orders efficiently to meet customer demands. |

| Increased Quality and Consistency | Improves output quality with precise design placements, enhancing customer satisfaction. |

| Technological Advancements | User-friendly software simplifies the design process for operators. |

| Competitive Edge | Faster turnaround times and quality assurance attract and retain clients. |

Summary

The DTF gangsheet builder is becoming an essential tool in print shops as it greatly improves operational efficiency, reduces waste, and boosts the quality of printed products. In today’s rapidly evolving market, adopting innovations like this helps shops maintain a competitive edge by meeting diverse customer demands and ensuring high customer satisfaction. As the demand for custom apparel continues to rise, print shops leveraging the DTF gangsheet builder will position themselves as leaders in the industry.