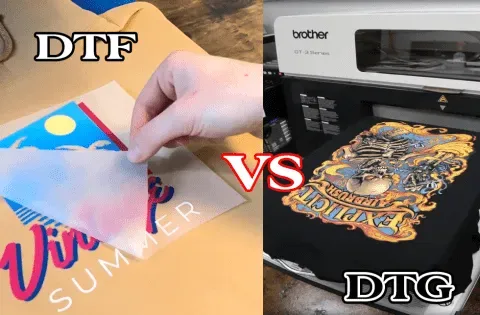

In the competitive landscape of custom apparel, the choice between DTF vs DTG printing can significantly influence your business’s success. DTF (Direct to Film) and DTG (Direct to Garment) are two of the leading printing methods that cater to different needs and preferences. While DTF printing offers versatility across a range of materials, DTG printing excels at delivering stunning visuals with intricate details on cotton fabrics. Understanding the nuances of these printing methods is crucial for businesses looking to optimize their custom apparel printing capabilities. This article will dissect the key differences and help you decide which option is best suited for your requirements.

When it comes to selecting a printing technique for your apparel, you may find yourself weighing the benefits of direct-to-film versus direct-to-garment methods. These printing technologies represent distinct approaches to bringing your designs to life on fabric, with each offering unique strengths and weaknesses. Whether you’re looking for high-quality prints on cotton or seeking versatility across different fabric types, understanding the fundamentals of DTF and DTG can aid in making an informed decision. Both terminologies reflect the advancements in the field of custom apparel decoration, ensuring businesses can cater to diverse consumer demands effectively. By exploring these printing methods comparison, you can identify the right fit for your creative endeavors.

The Basics of DTF Printing and DTG Printing

DTF printing, or Direct to Film printing, involves a meticulous process where designs are printed onto a specialized film. This film acts as a carrier for the ink, which is then transferred onto various fabrics, including cotton and polyester, using heat application. This method not only enhances versatility across different materials but also makes it suitable for intricate designs and vibrant color applications. As it allows for printing on a variety of surfaces, businesses have the freedom to expand their product offerings and cater to diverse customer preferences.

In contrast, Direct to Garment printing (DTG) employs an inkjet technology that enables printers to apply ink directly onto the textile. This process is particularly effective for producing high-resolution prints, capturing fine details and vivid colors on 100% cotton fabrics. DTG is often favored for custom apparel that requires detailed designs or photographic imagery. However, its reliance on cotton may restrict some businesses from utilizing this method for synthetic materials, which could limit their target market.

Frequently Asked Questions

What are the main differences between DTF printing and DTG printing?

DTF printing (Direct to Film) prints designs onto a film, which is then transferred to fabric with heat, allowing for versatility across various materials. In contrast, DTG printing (Direct to Garment) prints directly onto the fabric, offering high-resolution details but is primarily effective on 100% cotton.

Which printing method is more cost-effective for large orders: DTF or DTG?

DTF printing is generally more cost-effective for larger orders due to lower ink costs and quicker production times. DTG printing can become more expensive for higher volumes due to longer print times and maintenance costs.

Can you use DTF printing on different types of fabrics compared to DTG printing?

Yes, DTF printing offers greater versatility as it can print on various fabrics including cotton, polyester, and blends without requiring pre-treatment. DTG printing is best suited for cotton fabrics, which may limit its application.

What are the maintenance requirements for DTG and DTF printers?

DTF printers typically require less maintenance compared to DTG printers, which have more complex systems that need regular upkeep to prevent issues such as clogs, especially with infrequent use.

Is the print quality different between DTF and DTG printing methods?

Yes, DTG printing generally delivers superior print quality and detail, especially for intricate designs, whereas DTF prints can have a thicker feel due to the transfer process, but still produce vibrant colors.

For startups focusing on custom apparel, which method is recommended: DTF or DTG?

Startups may find DTF printing more advantageous due to its cost-efficiency, versatility with various fabrics, and ease of setup. This makes it a popular choice among small businesses in the custom apparel sector.

| Aspect | DTF (Direct to Film) | DTG (Direct to Garment) |

|---|---|---|

| Printing Process | Prints designs onto a film, then transfers them using heat, suitable for multiple fabric types. | Utilizes direct inkjet technology, best for high-resolution designs on cotton fabrics. |

| Quality and Detail | Provides good quality prints with vibrant colors, slightly thicker feel due to the transfer process. | Produces superior quality prints with better detail, ideal for intricate designs and smooth gradients. |

| Cost Effectiveness | More economical for larger orders with lower ink costs and faster print times. | Can be costlier for larger volume orders due to longer printing times and maintenance costs. |

| Setup and Maintenance | User-friendly with less maintenance, suitable for smaller businesses. | Requires extensive maintenance to prevent clogging, especially with infrequent use. |

| Flexibility and Versatility | Can print on a variety of fabrics with no pre-treatment, enabling diverse product lines. | Requires pre-treatment of fabrics, adding more labor and time to production. |

Summary

DTF vs DTG printing is a significant consideration for businesses in the custom apparel industry. While DTF offers versatility and cost-effectiveness, particularly for those starting out or needing to print on various fabrics, DTG excels in providing high-quality and detailed prints, particularly on cotton. Ultimately, the decision between DTF and DTG should align with your specific business needs, budget, and the nature of the designs you wish to create, ensuring you choose the method that best supports your goals.