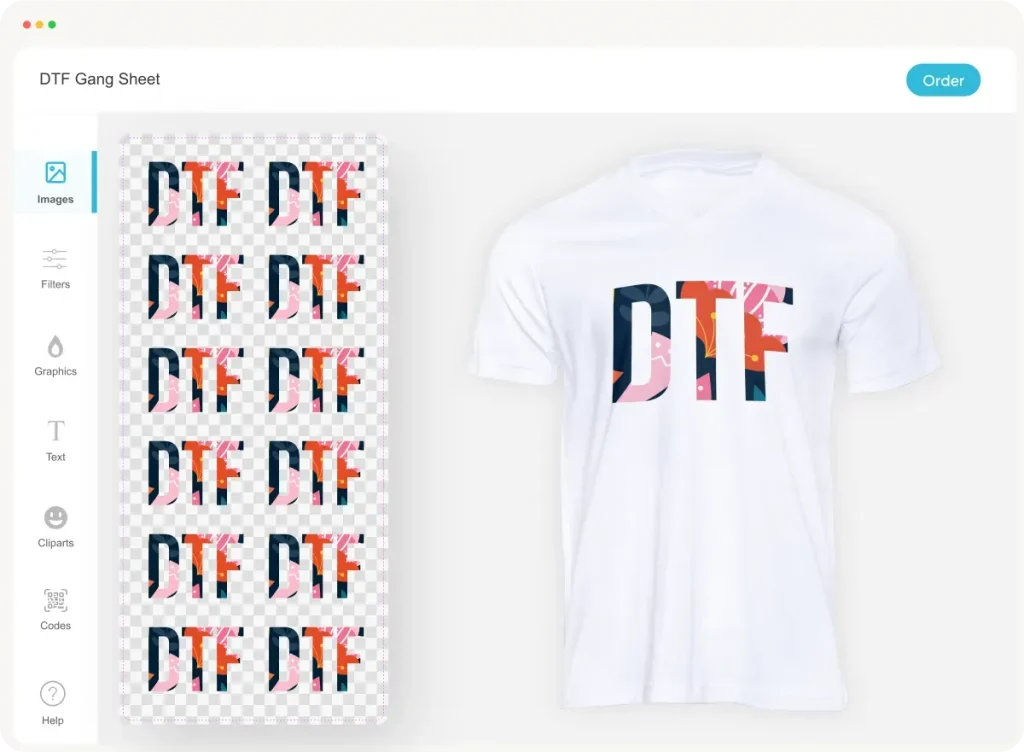

DTF Gangsheet Builder reimagines how designers plan each print run, turning multi-design layouts into a single, efficient workflow. In practice, it accelerates DTF transfers by placing multiple designs on one sheet while preserving color accuracy and alignment. Designed to work seamlessly with DTF printer software, it streamlines gangsheet design and reduces guesswork in setup. By defining safe margins, bleed, and export-ready files, it supports a reliable heat press for DTF operation. With built-in DTF workflow tips and a repeatable process, the tool helps teams scale production without compromising quality.

Think of it as a smart sheet-layout engine for direct-to-film projects, a multi-design sheet planner that optimizes every edge and margin. Alternative terms like gangsheet designer or batch layout tool share the same core promise: fast planning, consistent results, and reduced waste. This semantic approach (LSI) groups related terms such as DTF transfers, gangsheet design, DTF printer software, heat press for DTF, and DTF workflow tips to build a cohesive topic around sheet-based production. When paired with DTF printer software, the concept—DTF Gangsheet Builder—becomes the backbone for scalable production and repeatable results. Whether you call it a gangsheet optimization tool or a print layout system, the aim remains: faster transfers, stronger fidelity, and smoother DTF workflow tips.

Mastering DTF Transfers with a Streamlined Gangsheet Strategy

A streamlined gangsheet strategy dramatically accelerates DTF transfers by combining multiple designs onto a single sheet. This approach reduces handling time, minimizes waste, and helps you lock in consistent print parameters across a batch. When you optimize the gangsheet design, you also simplify post-processing and ensure more predictable results on every transfer.

Plan your batch with a clear layout map that notes margins, bleed, and the exact placement for each design. This foresight translates into faster setup, fewer adjustments during printing, and improved alignment across the entire run. By aligning your gangsheet strategy with your DTF workflow tips, you create a repeatable process that scales as your catalog grows.

Integrating with your DTF printer software ensures tiling accuracy and easy export of print-ready files. A well-planned gangsheet minimizes color changes and ink costs while maximizing sheet utilization, leading to faster throughput without sacrificing quality.

Design Principles for Consistent Gangsheet Design in DTF Printing

Gangsheet design hinges on a precise grid, robust alignment guides, and safe margins. These principles prevent edge-cutting and misalignment when the sheet is cut and pressed, while also enabling uniform application of color across all designs. When the layout is visually balanced, every transfer benefits from predictable spacing and clearer print quality.

Color management is essential for consistent results across designs. Calibrated color profiles, controlled bleed, and consistent margins help maintain uniformity, reducing color drift between designs on the same sheet. By integrating these design practices with DTF transfers workflows, you ensure repeatable outcomes that customers notice.

A strong gangsheet design translates to smoother pre-press checks and fewer reworks. Standardize element spacing, font sizes, and image placement so your team can reproduce successful layouts with minimal guesswork, ultimately boosting confidence in high-volume runs.

DTF Printer Software Integration: From Layout to Print

DTF printer software serves as the bridge between your gangsheet design and the printed sheet. It interprets the layout, applies color management profiles, and tiles large gang sheets into printer-ready files. A tight integration minimizes manual edits and ensures the file preserves exact positions and margins during production.

Use the software to preview soft proofs and verify color fidelity before committing to the actual print. Regularly update drivers and ICC profiles so your printer software stays compatible with new features and color capabilities. When export formats are clean and precise, the transition from screen to film to garment becomes seamless.

Export strategies matter: choose file formats and tiling options that your DTF printer software can easily interpret, and confirm that the export preserves all alignment cues, bleed settings, and boundary marks for precise transfer.

Choosing the Right Heat Press for DTF: Temperature, Pressure, and Time

The heat press is where your designs come to life, so selecting the right machine and settings is critical. For DTF, target temperatures in the 320–340°F (160–171°C) range and pressing times around 12–15 seconds, adjusting for fabric thickness and film specifications. Consistent heat and pressure across the entire sheet help ensure uniform bonding of all designs.

Pre-pressing the garment to remove moisture and viscous bonds improves transfer reliability, while even pressure across the platen prevents shifting or misalignment of designs during the final press. A press with even platen temperature distribution and reliable pressure settings will reduce the likelihood of cold spots and uneven adhesion, especially on larger gangsheet layouts.

Regular calibration and maintenance of your heat press for DTF, including routine platen cleaning and pressure testing, support consistent results batch after batch. This attention to press performance complements your optimized gangsheet design and printer workflow.

DTF Workflow Tips: Streamlining Batches for Fast, Flawless Results

DTF workflow tips center on planning ahead, standardizing processes, and documenting outcomes. Create a pre-batch checklist that covers design validation, export readiness, and printer setup to minimize last-minute delays. A consistent workflow reduces human error and helps teams reproduce high-quality results more reliably.

Track results across jobs by maintaining a simple log of settings, proofs, and outcomes. This data lets you quickly reproduce successful parameters and adjust workflows for new designs. Standardization—across design files, color profiles, and press times—reduces variability and speeds up batch turnover.

Invest in quality tools and regular training so operators stay proficient with the DTF workflow. From dusting powder to curing times, each step benefits from a well-documented procedure and continuous improvement based on team feedback.

The DTF Gangsheet Builder in Action: From Planning to Press

DTF Gangsheet Builder acts as the central planning hub, guiding you through layout creation, bleed management, and export to printer software. By mapping out all designs on a unified gangsheet, you streamline the entire production flow and minimize last-minute changes that disrupt throughput.

Begin with a planning phase that lists each design, its size, and any rotation required for optimal placement. Prepare artwork at high resolution, then import into the builder to arrange, align, and apply safe margins. This step reduces misplacements and aligns color blocks across multiple designs.

Export a print-ready file or a tiled set that your DTF printer software can translate into a smooth printing process. The builder’s output should preserve exact positions, margins, and bleed settings, supporting a repeatable press workflow and consistent results on fabric.

Frequently Asked Questions

How does the DTF Gangsheet Builder speed up DTF transfers and improve gangsheet design?

The DTF Gangsheet Builder speeds up transfers by pre-planning placements, standardizing margins and bleed, and exporting print-ready files that your DTF printer software can read without adjustments. It enforces consistent gangsheet design across batches, reduces misprints, and streamlines the heat press for DTF workflow.

What is gangsheet design in the context of the DTF Gangsheet Builder?

Gangsheet design is the layout of multiple designs on a single sheet. The DTF Gangsheet Builder provides grid-based placement, alignment guides, and safe margins to optimize sheet usage and ensure consistent spacing for all DTF transfers.

How does the DTF Gangsheet Builder integrate with DTF printer software?

It exports print-ready files or tiles compatible with your DTF printer software, preserving positions and margins and supporting color management. This minimizes manual adjustments and aligns with common DTF workflow tips.

What heat press for DTF settings are recommended when using designs created with the DTF Gangsheet Builder?

Typical guidelines are 320–340°F (160–171°C) for 12–15 seconds with firm, even pressure, plus a pre-press to remove moisture. Adjust as needed for fabric and film, ensuring consistent pressing to realize the gangsheet designs.

What DTF workflow tips help maximize efficiency with the DTF Gangsheet Builder?

Plan batch layouts ahead, standardize processes with checklists, track results and settings, calibrate printers regularly, and iterate based on feedback. The builder supports consistent color profiles and margins across designs, improving overall DTF transfers.

How does the DTF Gangsheet Builder support color management across multiple designs?

It provides color previews and works with your DTF printer software ICC profiles to map colors consistently across designs, reducing color drift in DTF transfers.

| Topic | Key Points |

|---|---|

| What is a DTF Gangsheet & DTF Gangsheet Builder | A gangsheet is a single printing sheet with multiple images; the DTF Gangsheet Builder streamlines layout, printer settings, and workflow to enable fast, flawless transfers. |

| Benefits of using a DTF Gangsheet Builder | Increases throughput, ensures consistent color and alignment, improves material efficiency; speeds batch setup and scales with growing catalogs. |

| Key Components of an Effective Gangsheet Design | Gangsheet design, color management, bleed and margins, and file export in a printer-friendly format. |

| Step-by-Step High-Level Workflow | Plan designs and layout; prepare artwork at 300 dpi+ (CMYK); place in grid with guides; manage color and proofing; export print-ready files; powdering; heat press; post-press checks; batch consistency tips. |

| Role of DTF Printer Software | Translates gangsheet designs into print-ready files; supports color management, tiling, and exporting; integrates with the builder; keep drivers/software up to date. |

| DTF Workflow Tips for Consistency & Growth | Plan ahead; standardize processes; track results; invest in quality tools; iterate using feedback to refine layouts and press settings. |

| Troubleshooting Common Issues | Misalignment between designs; color mismatch; poor adhesion on/moist fabrics; white ink opacity problems; film tearing or transfer sticking to the platen. |