DTF transfers maintenance is essential for keeping graphics vivid and the bond between ink, film, and fabric strong across many wears. Like any print technology, longevity hinges on a consistent routine of careful handling, washing, and proper pressing. This guide outlines practical steps that help you prevent wear, cracking, peeling, and fading while preserving color and texture. Whether you’re a hobbyist or running a small business, establishing a simple maintenance routine will pay dividends in print quality and customer satisfaction. By treating every garment with care, you’ll extend life and keep designs looking fresh wash after wash.

From a broader perspective, you can frame this topic as ongoing care for heat-transfer graphics rather than a one-off fix. DTF transfer maintenance is a useful frame, with longevity tips that emphasize consistent routines protecting color, adhesion, and the fabric, especially during frequent washes. Adopt clear, simple practices—wash cold, inside out, avoid harsh chemicals, and air-dry or tumble on low—so the print lasts. In this way, you translate technical care into everyday language readers can apply to garments, banners, or merchandise. Whether you’re mentoring a DIY team or stocking a storefront, steady habits turn maintenance into performance. Framing care this way also helps with searchability, as readers search for practical terms tied to longevity and reliable results. Keep a simple log of washes and heat settings to spot trends and refine your process over time. Together, these habits create a resilient foundation for DTF graphics that stay bright, flexible, and attractive across seasons. In practice, maintain a log of wash cycles and drying temperatures to spot patterns and adjust your setup. With patience and consistency, your DTF prints can endure routine laundering and sun exposure while staying crisp. Remember, always tailor the approach to your fabrics and transfer manufacturer guidelines for best results. The emphasis on consistent routine also helps you demonstrate value to customers by delivering durable, press-ready results.

DTF Transfer Care: Core Principles for Durable Graphics

DTF transfers deliver vibrant, durable graphics, but maintaining that look requires a thoughtful care routine. Effective DTF transfer maintenance hinges on protecting the bond between ink, film, and fabric, while practicing DTF garment care to minimize wear from washing, sun, and abrasion.

Adopt a simple, repeatable routine: wash garments inside-out on a gentle cycle with mild detergent, air dry when possible, and store away from direct sunlight. When needed, perform light DTF transfer cleaning—using a soft cloth and plain water—to remove surface dust without scrubbing the print.

Optimizing Heat Application for Strong Bonds

Precise heat application forms the foundation of a strong bond. Follow manufacturer recommendations for temperature, pressure, and time to ensure the transfer adheres evenly and resists cracking later. This careful calibration is a key part of overall DTF printing care.

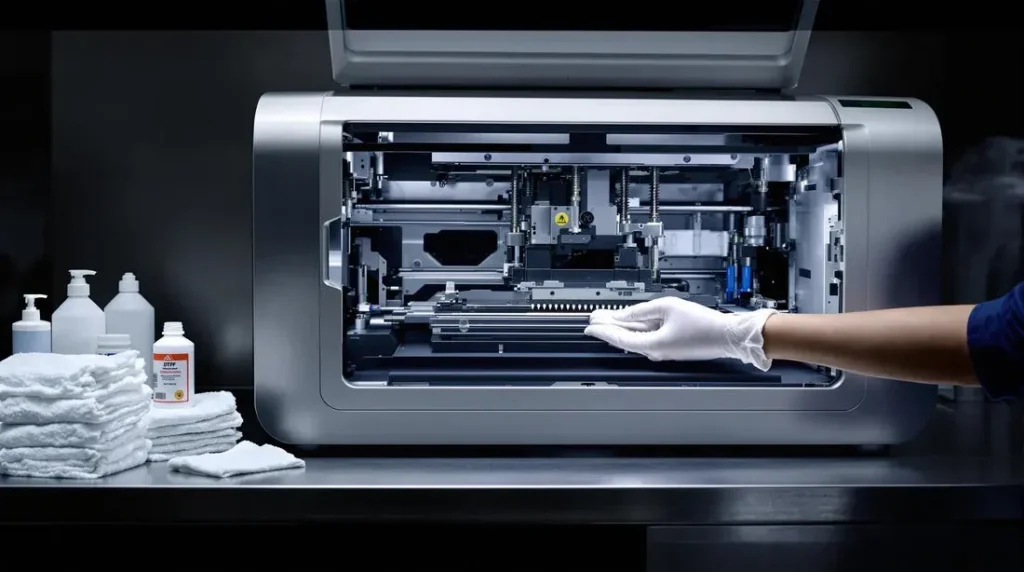

Invest in a calibrated heat press, reliable pressing pillows, and non-stick sheets to prevent edge scorching and hot spots. A patient, uniform press helps preserve adhesion and reduces the risk of edge lifting, aligning with solid DTF transfer maintenance practices.

DTF Longevity Tips: Maximize Color, Bond, and Wear-Resistance

DTF longevity tips emphasize reducing mechanical and chemical stress on the print. Keep cycles mild, wash cold, and turn items inside out to maintain color vibrancy and bond integrity over many wears.

Choosing fabrics with appropriate weight and weave improves performance; test on a small batch first; consider pre-treatments or finishing steps recommended by your supplier. Smart fabric selection supports durable DTF transfers and lowers rework, reinforcing the idea of good DTF garment care.

Care in Washing: DTF Printing Care for Pristine Prints

DTF printing care includes practical washing guidelines that preserve color and adhesion. Prioritize gentle cycles, cold water, and avoiding harsh chemicals that can degrade the surface or weaken the bond.

Limit drying heat and avoid fabric softeners; line dry when possible and keep prints out of direct sunlight to maintain pigment brightness. These practices are core elements of DTF garment care and overall print longevity.

Fabric Compatibility: Choosing Fabrics That Support DTF Transfers

Fabric compatibility matters. Heavier cotton blends and tightly woven materials tend to hold up best under repeated washes, while very light knits require careful tension management to prevent edge lift. This is a practical consideration in every DTF garment care plan.

Always test a small control run on a sample garment before full production; proper storage and handling also support longevity and reduce the likelihood of post-production issues, aligning with diligent DTF transfer maintenance.

DTF transfers maintenance: Common Issues, Prevention, and Repairs

DTF transfers maintenance is about proactive problem-solving. Peeling edges, cracking, or halos can signal improper pressing, edge stress, or detergent residue—catching these early helps avert customer-facing issues.

Fixes include adjusting heat, time, and pressure; re-press with correct settings; verify the release film and top sheet compatibility; when in doubt, run tests on a sample and consult the transfer supplier for guidance to sustain long-term results.

Frequently Asked Questions

What is DTF transfer maintenance and why is it essential for DTF longevity tips?

DTF transfer maintenance refers to the routines that protect the bond between ink, film, and fabric, preserving color and adhesion. Following manufacturer instructions, using a calibrated heat press, and careful handling are core steps in DTF transfer maintenance and support DTF longevity tips.

How can I perform DTF transfer cleaning as part of DTF garment care?

Cleaning should be gentle and sparing. Use a soft lint-free cloth dampened with plain water for surface dust, and avoid scrubbing near edges. For stains, treat off the print area with a mild detergent, avoid soaking, and skip harsh solvents that can affect adhesion.

Which DTF printing care practices help prevent cracking or peeling under DTF transfers maintenance?

Use proper heat press parameters, ensuring even pressure and following the transfer maker’s recommendations. Allow the garment to cool flat after pressing and avoid bending the print immediately; test settings with samples before production to prevent cracking or peeling.

What washing and storage steps maximize life for DTF transfers maintenance and DTF longevity tips?

Turn garments inside out, wash on a gentle cycle with cold or warm water and a mild detergent. Avoid chlorine bleach and fabric softeners that can weaken adhesion. Air dry or tumble dry on low, and store away from direct sun and heat to preserve color and bond.

What common issues can appear in DTF transfer maintenance and how can I fix them, like edge lifting or fading?

Peeling at edges often indicates edge stress or improper pressing—reassess pressure and time and re-press with correct settings. Cracking or fading usually comes from repeated washing or high heat; adjust temperatures, test on samples, and refine washing practices to maintain color and adhesion.

What tools and supplies support effective DTF transfer cleaning and DTF garment care?

Have soft, lint-free cloths and brushes, pH-neutral detergents, and diluted isopropyl alcohol for spot cleaning. Use heat press accessories like non-stick sheets and pressing pillows to ensure even heat, and keep top films, liners, and storage folders ready for ongoing DTF garment care.

| Aspect | Summary |

|---|---|

| Introduction | DTF transfers offer vibrant, durable graphics with a simpler workflow; maintenance affects longevity by preventing wear, cracking, peeling, and fading. Following practical tips helps hobbyists and small businesses maintain print quality over time. |

| What are DTF transfers and why maintenance matters | DTF transfers are designs printed on specialized film and heat-transferred to textiles. The transfer and ink are vulnerable to abrasion, washing, heat, and sunlight, so ongoing maintenance preserves color vibrancy and adhesion. The goal is to protect the image, strengthen the bond between ink, film, and fabric, and minimize conditions that weaken that bond. |

| Maintenance fundamentals | A solid plan combines proper pressing, careful washing, and thoughtful storage. Key actions: follow manufacturer recommendations; use quality equipment; protect prints during handling; wash with care; and manage dry and storage habits (air dry or low-heat tumble dry; store away from direct sun and heat). |

| Cleaning and upkeep | Clean the printed surface gently when needed. Surface maintenance with a soft cloth dampened with water; treat stains before washing; spot-clean with a mild soap solution or diluted isopropyl alcohol around the edges; avoid soaking and harsh solvents that can degrade the print. |

| Longevity tips | Maximize life by reducing stress on the print and fabric: optimize heat press parameters (e.g., 300–320°F / 150–160°C, 10–15 seconds, firm even pressure, following manufacturer guidance); use protective top film and liner; allow proper cooling after pressing; wash prints gently in cold water inside-out and avoid high heat; test on fabric samples before large runs. |

| Common issues and fixes | Peeling at edges: check edge bonding and adjust pressure/time; cracks/fading in wrinkles: adjust heat and fabric compatibility; loss of color vibrancy: minimize sun exposure and aggressive washing; white halos: ensure detergent residue is managed and film release is clean. |

| Tools, products, sources | Soft lint-free cloths and brushes; pH-neutral detergents without bleach; isopropyl alcohol 70% or less; heat press accessories (non-stick sheets, pressing pillows, silicone mats); storage solutions (clean, dry bins or folders). |

| Practical maintenance checklist | Daily/Per-use: handle with clean hands; wipe dust; store flat or on a hanger. Weekly: inspect prints for edge lift or color shift; adjust press settings; clean the press plate. Monthly: review washing practices; replace worn top films or liners; test a fresh transfer before larger production. |

Summary

The table above summarizes the key points from the base content about DTF transfers maintenance, including definitions, care fundamentals, cleaning routines, longevity tips, common issues, tools, and practical checklists.