Gangsheet Builder for DTF is transforming how shops scale, delivering faster turnarounds without sacrificing print quality. By optimizing how designs share space on a single sheet, teams can shorten setup times and reduce waste. This approach supports DTF workflow optimization by automating layout decisions and streamlining color handling. Consolidating multiple designs on one sheet boosts productivity while preserving print quality. And the handoff from design to print becomes faster and more reliable.

In practical terms, this technology enables smarter sheet planning, tighter color control, and fewer manual steps in the print room. Designs are grouped and arranged with careful attention to margins, bleeds, and cut lines, speeding up fulfillment and reducing errors. The approach complements existing DTF production pipelines by aligning with RIP workflows and color profiles to ensure consistency across jobs. As demand shifts toward high-variety runs, teams benefit from a cohesive sheet merge strategy that preserves quality while boosting throughput.

Maximizing DTF production efficiency with intelligent gangsheet layouts

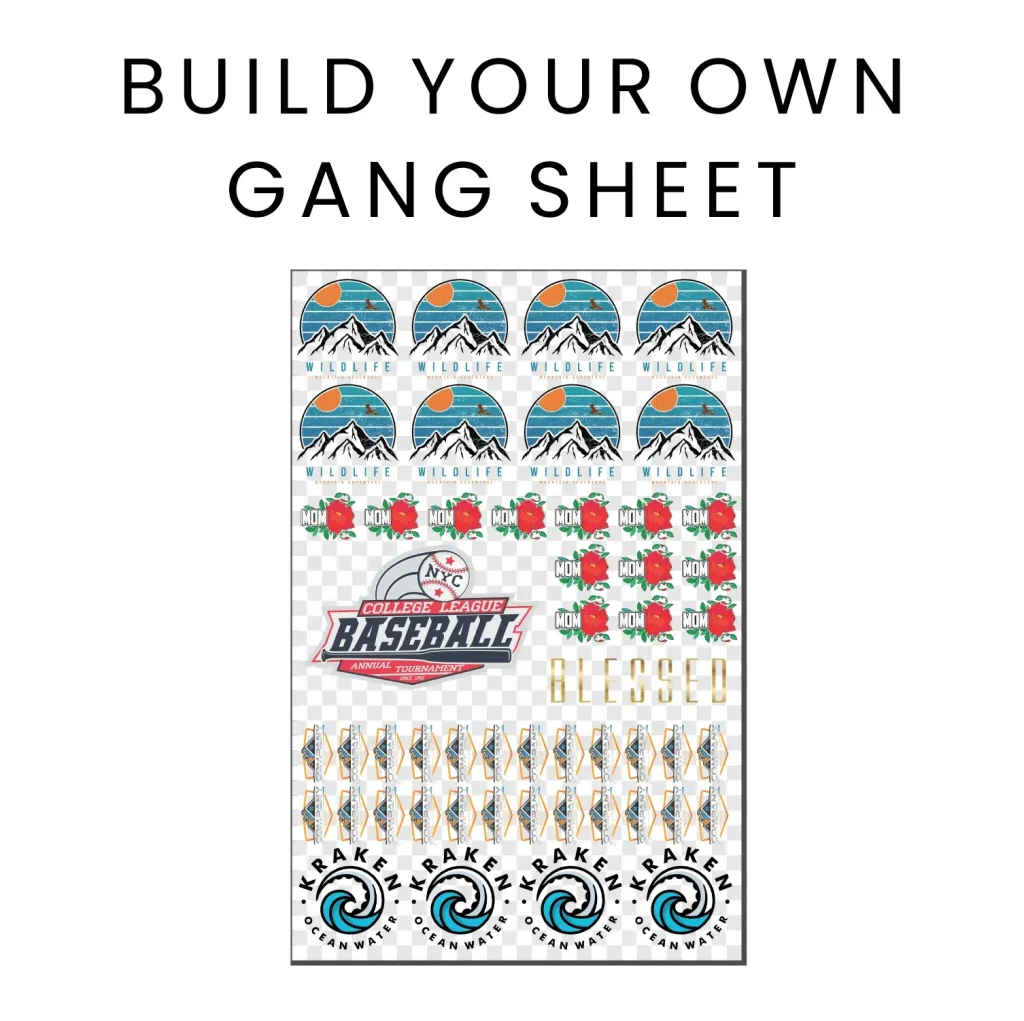

In the fast-paced world of DTF printing, efficient use of every sheet directly translates to faster turnarounds and lower costs. Intelligent gangsheet layouts optimize how multiple designs share a single print run, dramatically improving DTF production efficiency by reducing idle printer time and minimizing setup changes between jobs. This approach not only speeds up throughput but also helps brands meet tight deadlines without sacrificing quality, making every inch of substrate count.

A well-designed gangsheet printing plan leverages auto-layout and color-aware packing to maximize layouts while preserving color fidelity. By coordinating designs that share similar palettes and margins, you can cut ink waste and streamline finishing. When the printer and RIP work from a single, optimized gang sheet, you gain consistent results across designs and a smoother production cadence—key factors in achieving reliable DTF workflow optimization and scalable operations. Techniques like multi-design gang sheets further amplify efficiency by combining multiple product lines in one print run.

The fundamentals of gangsheet printing: saving substrate and ink on one sheet

Gangsheet printing centers on the idea of gathering several designs onto one printable sheet. This consolidation reduces substrate waste and lowers ink usage per order, which directly impacts the bottom line. By planning layouts that lock in space efficiently, shops can print more designs per sheet without compromising print quality or color accuracy, aligning with cost-conscious production goals.

Beyond maximizing sheet utilization, gangsheet printing requires careful attention to margins, bleed, and finishing compatibility. A coherent layout strategy minimizes misalignment during trimming and ensures predictable results across a range of products. Integrating color management considerations into the gang sheet from the start helps preserve consistent color representation, making it easier to maintain DTF quality at scale and support sustained growth of high-volume runs.

DTF workflow optimization through automation and templates

Automation is a cornerstone of modern DTF workflow optimization. By adopting templates and batch processing, you can reduce repetitive setup steps and accelerate every stage from design prep to print. Templates standardize placement, sizing, and color profiles, which minimizes human error and speeds up the handoff from design to production—critical for meeting tight delivery windows in e-commerce and custom apparel.

Integrating with your RIP and printer to push gang sheets automatically further enhances throughput and consistency. Automation removes manual file translation, ensures proper color management, and aligns with printer capabilities. When combined with a robust gangsheet strategy, automation accelerates the entire process—from file preparation to finished products—delivering more predictable output and better utilization of DTF printer automation capabilities.

Design strategies for multi-design gang sheets

Multi-design gang sheets enable brands to test combinations of products, sizes, and colorways within a single print pass. Thoughtful design strategies prioritize grouping designs with compatible color palettes and similar print requirements to minimize ink changes and downtime. This approach not only increases sheet throughput but also supports cohesive branding across collections, helping designers scale campaigns without fragmenting production.

When planning multi-design gang sheets, maintain consistent margins, bleed, and alignment cues to simplify cropping and finishing. Designing with finish options in mind—such as cut lines and seam placements—reduces post-print adjustments. A disciplined approach to layout also makes color management more predictable, which is essential for maintaining DTF production efficiency when handling large volumes and diverse product lines.

Gangsheet Builder for DTF: selecting tools and integration

A Gangsheet Builder for DTF is a specialized tool or process that automates layout, optimization, and preparation of gang sheets for your printer. Selecting the right builder means evaluating auto-layout capabilities, color-aware packing, multi-design gang sheets support, and seamless patching into your RIP. The goal is to reduce manual editing, speed up design-to-print transitions, and ensure the finished gang sheets are printer-ready.

Key considerations when choosing a builder include how well it integrates with your RIP and printer, whether it supports templating for recurring orders, and if it offers batch processing to scale up production. You should also assess its color management features, how it handles margins and bleed, and its ability to export in compatible formats. Pilot projects and vendor demonstrations can help verify that the Gangsheet Builder for DTF delivers tangible gains in DTF workflow efficiency and printer automation.

Measuring ROI and best practices for sustained efficiency in DTF operations

Investing in gangsheet strategies typically pays off quickly through reduced waste, lower ink costs, and faster turnarounds. ROI hinges on current waste and throughput; if you’re reclaiming idle printer time and decreasing setup iterations, even modest improvements can yield meaningful savings across many orders. As you scale, the cumulative impact on DTF production efficiency becomes more pronounced and supports competitive lead times.

To sustain gains, adopt a culture of continuous optimization. Regularly audit gang sheet layouts, maintain strict color discipline, and document standard operating procedures so new team members can ramp quickly. Track metrics such as sheets per hour, waste per job, color rework rates, and on-time delivery to quantify progress. A disciplined approach to measurement and iteration positions you to sustain gains in DTF workshop efficiency, maintain high-quality outputs, and expand through scalable, automated workflows.

Frequently Asked Questions

What is a Gangsheet Builder for DTF and how does it boost DTF production efficiency?

A Gangsheet Builder for DTF is specialized software or a process that automatically lays out multiple designs on one print sheet. It boosts DTF production efficiency by auto-layout optimization, color-aware packing, and direct printer automation, allowing more designs per gang sheet, reducing setup time, and cutting waste.

How does gangsheet printing with a Gangsheet Builder for DTF improve color consistency across designs?

Gangsheet printing with this builder coordinates layouts using consistent color profiles, margins, and a unified media path. This helps prevent color bleed, maintains calibration across designs, and delivers more uniform results in a single DTF print run.

Can a Gangsheet Builder for DTF handle multi-design gang sheets and different product sizes?

Yes. The builder supports multi-design gang sheets, enabling different products and sizes to share one sheet through templates and color management, which maximizes sheet usage without sacrificing print quality.

How does DTF workflow optimization and printer automation work with a Gangsheet Builder for DTF?

DTF workflow optimization and printer automation come from integration with your RIP and DTF printer. The builder can push gang sheets automatically, enable batch processing and automatic export, and reduce manual handling across the print workflow.

What are the key steps to implement a Gangsheet Builder for DTF in your shop?

Assess current workflow and bottlenecks; decide to build or buy the tool; create design templates and color profiles; integrate with your RIP and printer; run pilot prints to validate efficiency and quality; and train your team on the new process.

What ROI and best practices should you consider when adopting a Gangsheet Builder for DTF?

Expect ROI from reduced waste and ink, faster turnarounds, and higher throughput in DTF operations. Track metrics like sheets per hour and waste per job, and follow best practices such as auditing layouts, maintaining color discipline, documenting procedures, and iterating based on results.

| Aspect | Key Points |

|---|---|

| What is gangsheet printing and why it matters | A gangsheet is a single printable sheet containing multiple designs, reducing waste, ink, and setup time. A Gangsheet Builder for DTF automates layout and preparation to maximize designs per sheet while preserving print quality. |

| How it works | A gangsheet holds multiple designs on one sheet; the builder analyzes image sizes, color limits, and margins to generate a print-ready sheet that maximizes designs per sheet while preserving quality. |

| Benefits of scaling production | Higher throughput with less idle time; consistent color and quality across designs; reduced waste and ink usage; faster time-to-fulfillment for ecommerce. |

| Core features | Auto-layout optimization; color-aware packing; multi-design gang sheets support; seamless file prep with RIP compatibility; batch processing and templating; printer automation integration. |

| Implementation steps | Assess current workflow and pain points; build or buy the right builder (standalone, plugin, or integrated); create design templates and color profiles; integrate with RIP and printer; run pilot prints; train your team. |

| Maximizing efficiency | Consolidate designs with similar color palettes; use consistent design margins and bleed; plan for post-print finishing; optimize substrate usage with best grid layouts; leverage multi-design gang sheets for campaigns. |

| DTF workflow optimization and automation benefits | Reduced manual intervention; consistent throughput; improved accuracy and repeatability; better job quoting and planning. |

| ROI considerations | Lower waste and ink costs from improved layouts; faster turnaround times; capex vs opex considerations; scalability across more designs, larger sheet sizes, and multiple RIPs. |

| Best practices | Regular layout audits; maintain color discipline; document standard operating procedures; measure and iterate with metrics (sheets/hour, waste, rework). |

Summary

Gangsheet Builder for DTF is a transformative approach to production designed to maximize substrate usage, reduce waste, and accelerate order throughput. It orchestrates auto-layout, color-aware packing, and printer automation to create print-ready gang sheets that preserve color fidelity across designs and scale your DTF operations. With standardized templates, streamlined RIP exports, and automated layouts, you can achieve more consistent results, faster turnarounds, and a stronger return on investment as your product lines expand.