California DTF Printing is reshaping how creators, small businesses, and hobbyists bring bold designs to life on a wide array of fabrics, merging accessibility, speed, and high-quality results into a practical, scalable solution. DTF printing offers vibrant colors, a soft hand-feel, durable results, and the flexibility to print on everything from cotton tees to performance fabrics, while keeping production costs reasonable for small runs and custom orders. If you’re new to the world of direct-to-film, you’ve picked a great time to dive in, because rising availability of ink sets, film, and heat-transfer tools makes experimentation approachable for beginners and seasoned makers alike. This beginner-friendly guide covers the basics you’ll need, from choosing the right equipment and materials to mastering color management, curing, and transfer parameters, all explained with practical tips that you can apply immediately. From your first test print to launching a small studio network in California, the DTF workflow supports creative experimentation, quick turnarounds, and the ability to scale as demand grows.

Beyond the branded term, the same approach can be described as direct-to-film transfer, DTF film transfer, film-to-fabric printing, or digital textile transfer, all using a printable film and ink system to create durable designs. In practice, you print onto a specialty transfer sheet, apply a bonding powder, cure, and then press the film onto the garment with controlled heat and pressure to achieve vibrant results. If you’re evaluating equipment or suppliers, look for terminology such as heat press for DTF, white-ink capabilities, and compatibility with a range of fabrics to ensure a flexible, scalable workflow.

Getting Started with Direct-to-Film (DTF) Printing: A Beginner’s Roadmap

If you’re new to DTF printing, Direct-to-Film offers a friendly entry into fabric design. DTF printing uses a special transfer film and inks to move vibrant designs onto textiles, delivering a soft hand feel and the flexibility to print on a wide range of fabrics. This beginner-friendly approach helps you explore color, texture, and adhesion without the high upfront complexity of other methods.

This roadmap covers the essentials of DTF film transfer, the basic gear you need, and practical tips to start printing with confidence—whether you’re working from a home studio or a small shop. As you gain experience, you’ll learn to calibrate color, fine-tune transfer settings, and expand your product line with confidence.

Choosing the Right DTF Equipment and Materials for Your Studio

Selecting a reliable DTF printer that supports white ink for vibrant on-dark fabrics is the first step. Pair the printer with compatible DTF inks, a quality transfer film, and a bonding powder to create durable transfers. The right combination affects color accuracy, opacity, and the ease of the overall process.

Don’t overlook the importance of a solid heat press for DTF and essential accessories like Teflon sheets, silicone mats, and protective gloves. Regular maintenance, such as printer head cleaning and substrate calibration, helps ensure repeatable results and reduces downtime between orders.

Color Management and Pre-Press Best Practices for Vivid DTF Results

Color management is critical in DTF printing. Calibrate your printer with proper color profiles, manage separations, and plan pre-press steps such as garment cleaning and ensuring substrate compatibility. When printing on dark fabrics, a white base underprint is often required to keep colors bright and true.

Run test prints and proofs to verify color density, texture, and adhesion before customer orders. Build a library of reliable color profiles and document substrate notes for consistency across runs, whether you’re working with polyester, cotton blends, or other materials.

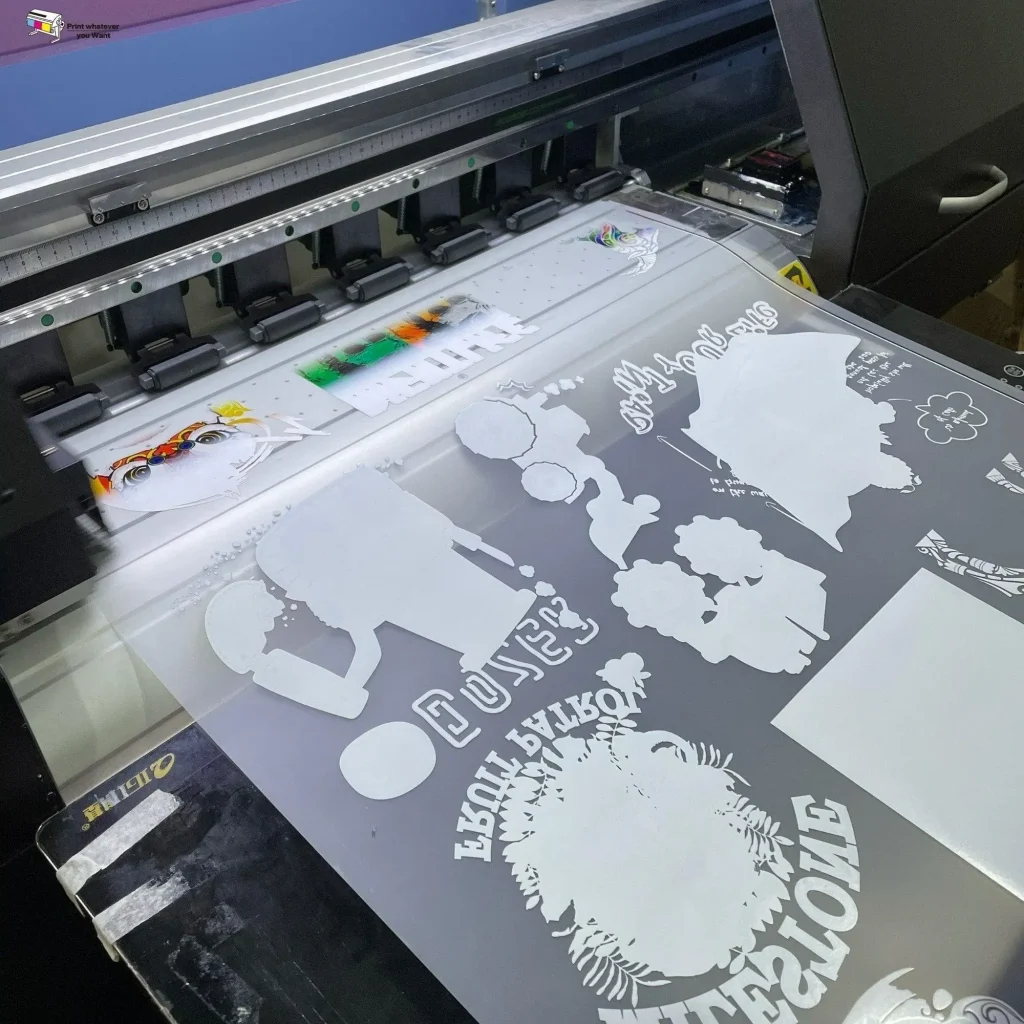

Executing the DTF Transfer: From Film to Fabric with a Reliable Heat Press

Executing the transfer involves printing on the film, applying a bonding powder, curing, and then transferring the design to the garment. This process, commonly referred to as DTF film transfer, relies on careful timing, temperature, and film handling to deliver crisp lines and durable results.

Set your heat press for DTF with repeatable, fabric-specific profiles. Key factors include temperature, dwell time, and pressure, plus a cooling step if recommended for your substrate. Proper protection with sheets and a clean workstation helps prevent smudging and ensures consistent hand feel and wash durability.

California DTF Printing Success: Launching a Local DTF Business and Growth

California DTF Printing is transforming how creators scale custom apparel in a state with a vibrant design community. The local ecosystem—suppliers, training resources, and peer networks—supports beginners turning ideas into finished garments and profitable ventures.

To grow a DTF printing business in California, navigate local regulations, licensing, and environmental considerations while leveraging batch production, print-on-demand options, and diverse substrate offerings. Engaging with regional events, building a portfolio, and collaborating with local brands can accelerate learning and expand your customer base while staying aligned with the latest DTF printing trends.

Frequently Asked Questions

What is California DTF Printing and how does direct-to-film (DTF) printing work for apparel?

California DTF Printing uses direct-to-film technology to print designs onto a transfer film, which is then coated with a bonding powder, cured, and transferred to fabric with a heat press. This method yields vibrant colors, a soft hand feel, and compatibility with a wide range of textiles, offering a flexible alternative to screen printing or DTG.

What equipment do I need for California DTF Printing, and where does a heat press for DTF fit in?

Essential gear includes a DTF printer (with white ink capability), DTF inks, transfer film, bonding powder, a curing step, and a heat press for DTF. Add heat press accessories (Teflon sheets, silicone sheets) and post-processing tools. The heat press is used to transfer the printed film to the garment under controlled temperature, time, and pressure for reliable results.

How should I prepare designs and manage color for California DTF Printing using direct-to-film?

Prepare artwork with proper bleed and color separations, then print on film using a DTF printer. Manage color with calibrated profiles, and use a white ink underprint for dark fabrics to maintain brightness. Pre-press steps like garment cleaning and substrate compatibility help ensure accurate color and durability.

Which fabrics work best with California DTF Printing and DTF film transfer, and how should I test substrates?

DTF printing supports a wide range of textiles, including cotton blends and poly blends. Dark fabrics often need a white base underprint, and you should test color, texture, and adhesion on your target fabrics before taking on orders to dial in transfer parameters.

What are common challenges in California DTF Printing and how can I troubleshoot issues like white ink underperformance or powder adhesion?

Common issues include fading or banding, white ink underperformance on dark fabrics, powder not adhering, and residue on films. Troubleshoot by verifying ink density, ensuring proper curing, checking transfer film quality, and confirming even powder application and correct heat-press settings. Maintaining your equipment and running test prints helps build consistent results.

| Key Topic | Summary |

|---|---|

| What is Direct-to-Film (DTF) Printing | Transfers printed designs from film to textiles using heat press; prints on film with inks, bonding powder, cure, then transfer; crisp, vibrant, durable; lower entry barrier and creative freedom. |

| Why California DTF Printing is Gaining Traction | Thriving maker/apparel community in California; diverse fabrics and a dense custom apparel market; DIY branding culture; favorable for startups and printers; growing supplier/train networks. |

| Essential Equipment & Materials | DTF printer (with white ink if printing on dark fabrics), DTF inks, transfer film, powder binder, curing step, heat press and accessories, post-processing tools, testing materials. |

| Planning Your Workflow | Design → color separation → print on film → apply powder → cure → transfer; calibrate and run test prints to improve color fidelity and durability. |

| Color Management & Pre-Press | Calibrate printer and color profiles; pre-press includes garment cleaning and substrate compatibility; white base on dark fabrics helps colors pop. |

| DTF Process Stages in a California Studio | Design/setup; printing on film; powder application; curing; transfer; post-transfer care. |

| Settings for DTF Printing | Use manufacturer baselines; adjust for fabric type, color density, and hand feel; tune temperature, dwell time, pressure, cooling. |

| Design Considerations for Beginners | High-contrast images, clean vector lines, test prints; tailor designs to California markets with local icons/themes; supports multiple fabrics. |

| Quality Assurance & Common Challenges | Fading/banding; white ink underperformance on dark fabrics; powder adhesion; residue; maintain consistent printer maintenance and proper curing. |

| Maintaining Your DTF System | Regular printhead cleaning, proper ink storage, monitor bonding powder/film; reduces waste and extends printer life. |

| Growth & Scaling | Build design libraries, batch production, invest in better films/powders, expand substrates, use sample kits to show clients. |

| Business & Compliance (California) | Understand local licenses, labor laws, environmental considerations; maintain compliant workspace to avoid issues. |

Summary

Conclusion: California DTF Printing has a practical, scalable path for turning designs into durable apparel and textiles. By mastering the core process, selecting reliable equipment, and dialing in color management and transfer parameters, beginners can achieve professional results. As you build experience, you’ll expand product lines, refine workflows, and connect with California customers. Practice, document settings, and stay curious about new materials and techniques to grow from a newcomer to a skilled DTF printer who delivers high-quality prints consistently.