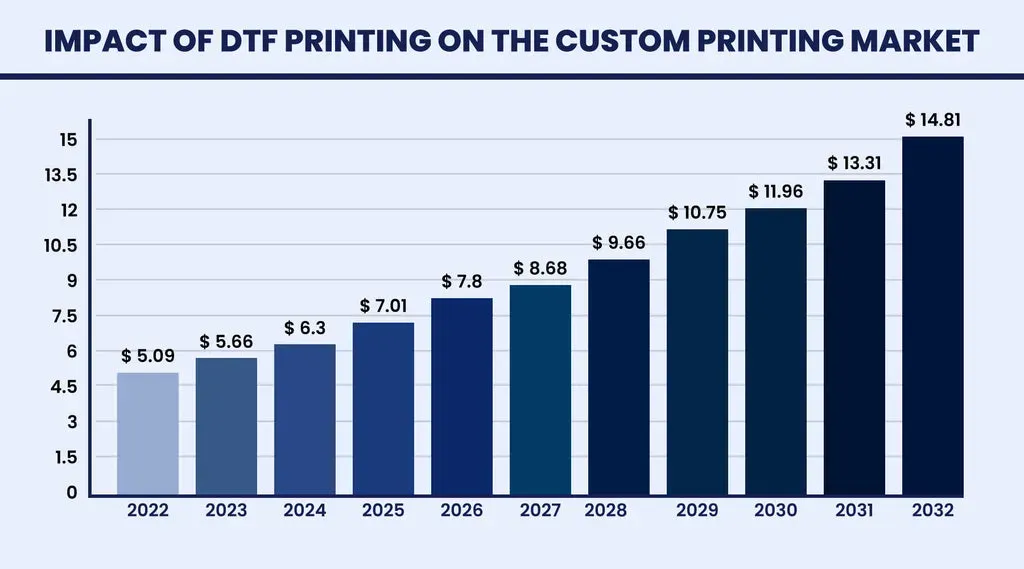

California DTF Market Outlook is a barometer for printers, brands, and material suppliers across a state known for innovation in apparel, merch, and customization. As Direct-to-Film (DTF) technology matures, the DTF market outlook 2025 will reshape capacity, pricing, and service offerings. The focus on simplicity, vibrant color, and durable transfers makes the technology appealing for short runs, on-demand orders, and regional production. This post distills the core dynamics and opportunities and risks for stakeholders—from small screen-printers to large garment factories. By weaving together market signals, technology trends, and regional conditions, we can understand how the market is evolving and what it means for the broader Direct-to-Film printing ecosystem in California.

Viewed through an alternate lens, the topic translates to on-demand garment decoration and digital transfer technology spreading across California’s print shops. That latent semantic framing surfaces related ideas like short-run customization, rapid prototyping, and eco-conscious production that align with evolving market dynamics. By discussing these linked concepts—such as rapid design iteration, workflow automation, and resilient supplier networks—we apply LSI principles to describe the same trend from multiple angles.

California DTF Market Outlook: What It Means for Printers and Brands

The California DTF Market Outlook serves as a barometer for printers, brands, and material suppliers operating in a state known for rapid innovation in apparel and merchandise. As Direct-to-Film technology matures, California businesses are evaluating how 2025 and beyond will reshape capacity, pricing, and service offerings. The trend toward on-demand production and shorter lead times makes DTF transfers market California a compelling option for regional production, helping shops scale with flexibility while maintaining high color fidelity and durable finishes.

Looking ahead, the DTF market outlook 2025 points to broader adoption driven by smarter workflows, better consumables, and automation that preserves quality at volume. In California, nearshoring advantages—from proximity to fashion hubs to streamlined logistics—support a more resilient supply chain for Direct-to-Film printing California. Stakeholders should monitor shifts in cost-per-unit for small runs and the evolving expectations of brands accustomed to rapid restocks and customizable drops, all within the context of California printing industry trends 2025.

Direct-to-Film Printing California: Technology Trends Driving Growth

Technology and product developments in Direct-to-Film printing California are expanding the range of fabrics and applications that shops can serve. Expect gradual improvements in inks and powders that raise color gamut, adhesion, and cure times, enabling softer hand-feel transfers on a wider variety of materials. The California DTF Market Outlook benefits from membrane and adhesive chemistry advances that broaden fabric compatibility, including blends and performance textiles common in regional markets.

Workflow automation and quality control are becoming mainstream as more shops adopt standardized prepress, RIP software, and automated curing and finishing lines. These innovations reduce bottlenecks, improve consistency across batches, and support higher throughput without sacrificing durability. From a California perspective, investments in automation-friendly workflows align with DTF transfers market California expectations for reliability, reduced waste, and scalable production.

California Printing Industry Trends 2025 and the DTF Market Outlook

Broad California printing industry trends 2025 emphasize efficiency, customization, and sustainability as core expectations in a competitive market. Printers across the state are evaluating how Direct-to-Film printing California can lower setup costs for small runs while delivering vibrant, durable transfers that appeal to fashion, sports, and promotional segments. The convergence of logistics improvements, skilled labor pools, and proximity to fashion-forward brands creates a favorable environment for early adopters within the DTF market outlook 2025.

Sustainability and waste reduction are increasingly central to decision-making, with standardized testing for wash durability and color fastness becoming routine as more shops scale. This aligns with broader California printing industry trends 2025, where customers demand responsible production and transparent performance data. As the ecosystem matures, printers can differentiate themselves by combining high-quality DTF transfers with efficient operations and credible environmental credentials.

DTF Transfers Market California: Opportunities in On-Demand and Private-Label

The DTF transfers market California presents opportunities for on-demand drops, private-label collaborations, and co-branding with local studios and designers. By leveraging California DTF market dynamics, brands can test concepts quickly, restock limited editions, and introduce seasonal designs with minimal risk. The flexibility of Direct-to-Film transfers makes it feasible to offer low-quantity batches that still deliver print quality and durability that meet consumer expectations.

Beyond production runs, the market supports training and consulting services that help shops optimize color management, fabric compatibility, and workflow optimization. As California printing industry trends 2025 mature, there is growing demand for specialized know-how in DTF transfers market California, enabling operators to command premium service offerings and build lasting partnerships with retailers and influencers who value fast turnarounds and transparent pricing.

Strategic Playbook for Stakeholders in California’s DTF Ecosystem

For printers and studios, the playbook emphasizes automation-friendly workflows, robust color management, and a curated catalog of fabric-specific transfer profiles to shorten lead times. Investing in scalable processes helps maintain consistency across batches while expanding capacity to meet rising demand within the California DTF market. These steps align with Direct-to-Film printing California best practices and the ongoing evolution of the DTF market outlook 2025.

For brands and retailers, partner with local California printers who can offer quick turnarounds and transparent pricing to capitalize on on-demand, regionally produced products. Suppliers should focus on high-quality consumables and equipment that maximize durability and color fidelity, while providing strong technical support for the California market. Educators and associations can advance adoption through hands-on workshops and certification programs tailored to California printing industry trends 2025, helping shops upscale capabilities and stay competitive in the DTF transfers market California.

Frequently Asked Questions

What does the California DTF Market Outlook say about growth for Direct-to-Film printing California in 2025?

The California DTF Market Outlook highlights rising capacity, smarter workflows, and better consumables, supported by Direct-to-Film printing California adoption as brands demand on-demand customization. This creates a favorable environment for California printers through 2025.

Which opportunities in the DTF transfers market California are highlighted by the California DTF Market Outlook?

Key opportunities include on-demand drops for local brands, private-label and co-branding, and education and training services for California printers. These trends position DTF transfers market California as a flexible solution for rapid prototyping and small runs.

What risks does the DTF market outlook 2025 identify for California printers in Direct-to-Film printing California?

Risks include supply chain volatility for inks and films, IP protection challenges with on-demand customization, and the need for standardized quality control across fabrics.

How can printers align with California printing industry trends 2025 within Direct-to-Film printing California to stay competitive?

Invest in automation-friendly workflows, robust color management, and fabric-specific transfer profiles to align with California printing industry trends 2025 and remain competitive in Direct-to-Film printing California.

How are lead times and pricing affected in the DTF market California according to the California DTF Market Outlook?

The outlook suggests shorter lead times and cost efficiencies for short runs, enabling competitive pricing in the DTF market California, while margins depend on steady consumables supply and efficient workflows.

| Topic | Key Points |

|---|---|

| Market snapshot and growth drivers |

|

| What data suggests about 2025 and beyond |

|

| Main drivers shaping the California DTF Market Outlook |

|

| Technology and product trends in Direct‑to‑Film printing |

|

| Regional dynamics: California‑specific considerations |

|

| Competitive landscape and market opportunities |

|

| Challenges and risk considerations |

|

| Strategic recommendations for stakeholders |

|