In the competitive landscape of custom printing, the DTF Gangsheet Builder has emerged as an essential tool for maximizing productivity and quality. This innovative solution allows print operators to utilize optimized printing techniques that streamline the DTF (Direct to Film) printing process. By effectively harnessing gang sheet printing, users can prepare multiple designs on a single sheet, substantially reducing waste while enhancing color vibrancy. Essential to achieving top-notch results is meticulous artwork preparation for DTF, which sets the stage for stunning outputs. Coupled with precise printer settings for DTF, the DTF Gangsheet Builder transforms how businesses approach print production, making it a game-changer in the industry.

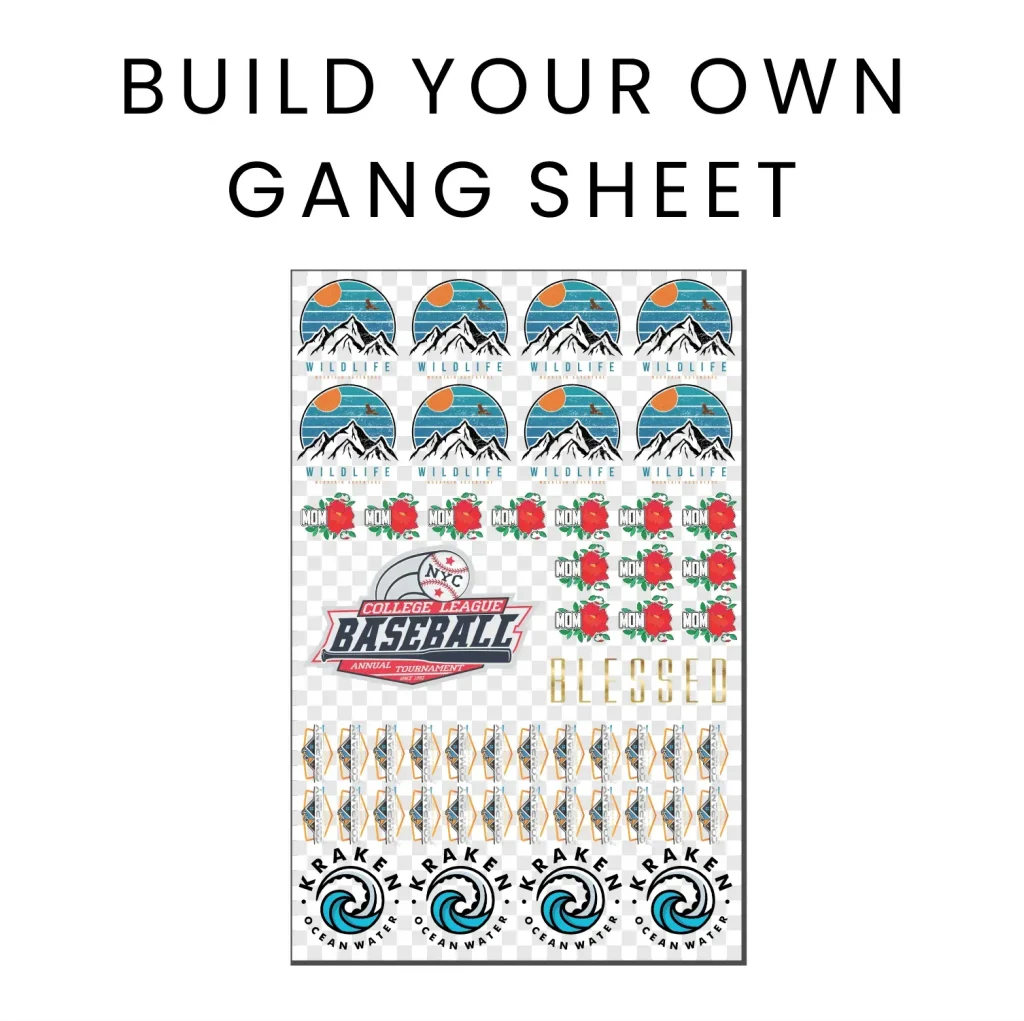

To dive into the realm of DTF printing, one must first grasp the importance of utilizing gang sheets effectively. Gang sheet printing refers to the process where various designs are simultaneously printed on a single film sheet, allowing for greater efficiency and minimal material wastage. By employing refined methods for design layout and ink management, print operators can achieve impressive results in their output quality. The effectiveness of artwork preparation for DTF plays a crucial role in this process, ensuring that every element aligns perfectly on the film. As operators fine-tune their printer settings for DTF, the convergence of these strategies leads to exceptional and vibrant printed designs.

The Power of DTF Gangsheet Builder in Custom Printing

The DTF Gangsheet Builder revolutionizes custom printing by enabling multiple designs to be printed at once, thereby improving operational efficiency. This tool allows print operators to create gang sheets that maximize space on the film, significantly reducing material waste. By understanding the structure of gang sheets, operators can effectively position various designs without compromising quality, thus harnessing the full potential of DTF printing technology.

Moreover, the DTF Gangsheet Builder optimizes production processes by allowing for better planning and organization of print jobs. It empowers operators to experiment with different design combinations on a single sheet, leading to innovative results. As the demand for customized prints grows, utilizing the gangsheet builder means adapting to changing market needs while ensuring consistent quality across all outputs.

Essential Techniques for Artwork Preparation in DTF Printing

Artwork preparation is a pivotal step in achieving high-quality prints using the DTF Gangsheet Builder. The foundation of successful artwork lies in correct dimensions; artwork that exceeds the gang sheet size can lead to cropped images and wasted materials. Print operators should prioritize resizing images accurately and previewing their layout to ensure everything fits perfectly before hitting print.

In addition to size, color management plays a vital role in artwork preparation. Operators must utilize appropriate color profiles to ensure that their prints maintain the vibrancy and fidelity of the original design. Misalignment in color settings can result in unanticipated outcomes, affecting not just the aesthetics, but also customer satisfaction. Thus, careful attention to these details in artwork preparation can make the difference between a mediocre print and a stunning one.

Optimizing Ink Usage for Vibrant Prints

Optimizing ink usage is a crucial aspect of using the DTF Gangsheet Builder effectively. By properly calibrating ink density settings, print operators can achieve vibrant colors without oversaturating the designs. Oversaturation not only affects the clarity of prints but can also lead to excessive ink bleeding, which compromises the professional appearance of the final product.

Moreover, managing the number of layers within designs helps maintain quality while controlling ink consumption. Each layer requires specific adjustments in density to achieve the desired outcome. By utilizing testing and feedback loops, operators can refine their approach to ink utilization, ensuring that each print not only meets quality expectations but also aligns with the efficiency goals of the operation.

Key Printer Settings for DTF Printing Success

The settings on your printer are paramount when it comes to executing successful DTF prints. Fine-tuning parameters such as temperature and speed are essential for achieving the right ink adhesion and drying effect. Too fast a speed can prevent the ink from settling correctly, leading to poor quality results. Therefore, adjusting these settings based on each specific print job can significantly enhance the overall outcome.

In addition, pre-treating the film surface before printing can provide a better foundation for ink adhesion. Experimenting with various pre-treatment processes can yield improvements in print durability and vibrancy. Operators should document results to determine the most effective approaches for their individual printing environments, ensuring that technical adjustments contribute positively to print quality.

The Importance of Testing and Quality Control in DTF Printing

Implementing robust testing protocols is invaluable in the DTF printing process. Conducting test prints before full production can uncover potential issues with color accuracy and design clarity. Early detection of inconsistencies helps avoid costly mistakes in bulk orders, ultimately saving both time and materials.

Quality control also encompasses monitoring the durability of prints by validating them against customer standards. Adjusting printing techniques based on test prints allows for continuous improvement in the production process, ensuring that each output meets the highest quality expectations. As a result, establishing a thorough testing and quality control regimen enhances the reliability of print operations and strengthens customer trust.

Maximizing Efficiency with DTF Gangsheet Applications

DTF gangsheet applications offer significant efficiency enhancements in the custom printing landscape. By enabling the printing of multiple designs on one sheet, operators can complete jobs faster without sacrificing quality. This streamlined process reduces the number of separate print runs, thus maximizing workflow and minimizing turnaround times.

The flexibility of gang sheets also allows for greater creativity and experimentation with design concepts. Printing smaller quantities of various designs at once promotes an agile operation, catering to diverse client needs effectively. Embracing these applications means not only enhancing productivity but also staying competitive in a rapidly evolving market.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve DTF printing efficiency?

The DTF Gangsheet Builder is a tool designed for Direct to Film (DTF) printing that allows multiple designs to be printed on a single sheet of film. This optimized printing technique increases efficiency by maximizing space and reducing material waste, ultimately speeding up the production process.

How can I prepare artwork effectively for the DTF Gangsheet Builder?

Proper artwork preparation for the DTF Gangsheet Builder involves ensuring the right dimensions, using appropriate color settings, and organizing design layouts effectively. These steps help achieve consistent, high-quality prints while minimizing errors in the production process.

What are the key printer settings necessary for successful gang sheet printing?

Key printer settings for successful DTF gang sheet printing include calibrating temperature for proper ink adhesion, adjusting print speed to ensure quality, and pre-treating the film to create a receptively surface. These adjustments are crucial for achieving the best outcomes in DTF printing.

What precautions should I take to optimize ink usage when using the DTF Gangsheet Builder?

To optimize ink usage with the DTF Gangsheet Builder, adjust ink density based on design requirements and monitor the number of ink layers per design. This approach helps maintain color vibrancy while preventing issues like oversaturation and extended drying times.

Why is testing and quality control important in the DTF Gangsheet Builder process?

Testing and quality control are vital in the DTF Gangsheet Builder process because they allow you to validate color accuracy, check for design clarity, and identify any potential issues with the printer or settings before entering full production, minimizing waste and costs.

What are the advantages of using gang sheets in DTF printing?

The use of gang sheets in DTF printing offers several advantages: it optimizes material use, reduces production time, lowers costs, and allows for multiple designs to be printed simultaneously, enhancing overall efficiency in the printing process.

| Key Points | Description |

|---|---|

| Understanding Gang Sheets | Gang sheets allow multiple designs to be printed on one sheet, improving efficiency and reducing waste. |

| Preparation of Artwork | Ensure correct dimensions, use appropriate color settings, and organize designs for optimal ink balance. |

| Optimize Ink Usage | Manage ink density and layers to maintain print quality and reduce drying time. |

| Printer Settings | Calibrate temperature, adjust speed, and pre-treat film for optimal ink adhesion. |

| Testing and Quality Control | Conduct test prints to ensure color accuracy and identify potential issues before full production. |

Summary

DTF Gangsheet Builder serves as a vital tool that elevates the quality and efficiency of custom printing processes. By understanding the principles behind gang sheets, preparing artwork meticulously, optimizing ink usage, refining printer settings, and performing thorough testing, print operators are well-equipped to enhance their production outcomes. Effective use of the DTF Gangsheet Builder not only minimizes material waste but also guarantees vibrant, high-quality prints, making it indispensable for modern printing operations.