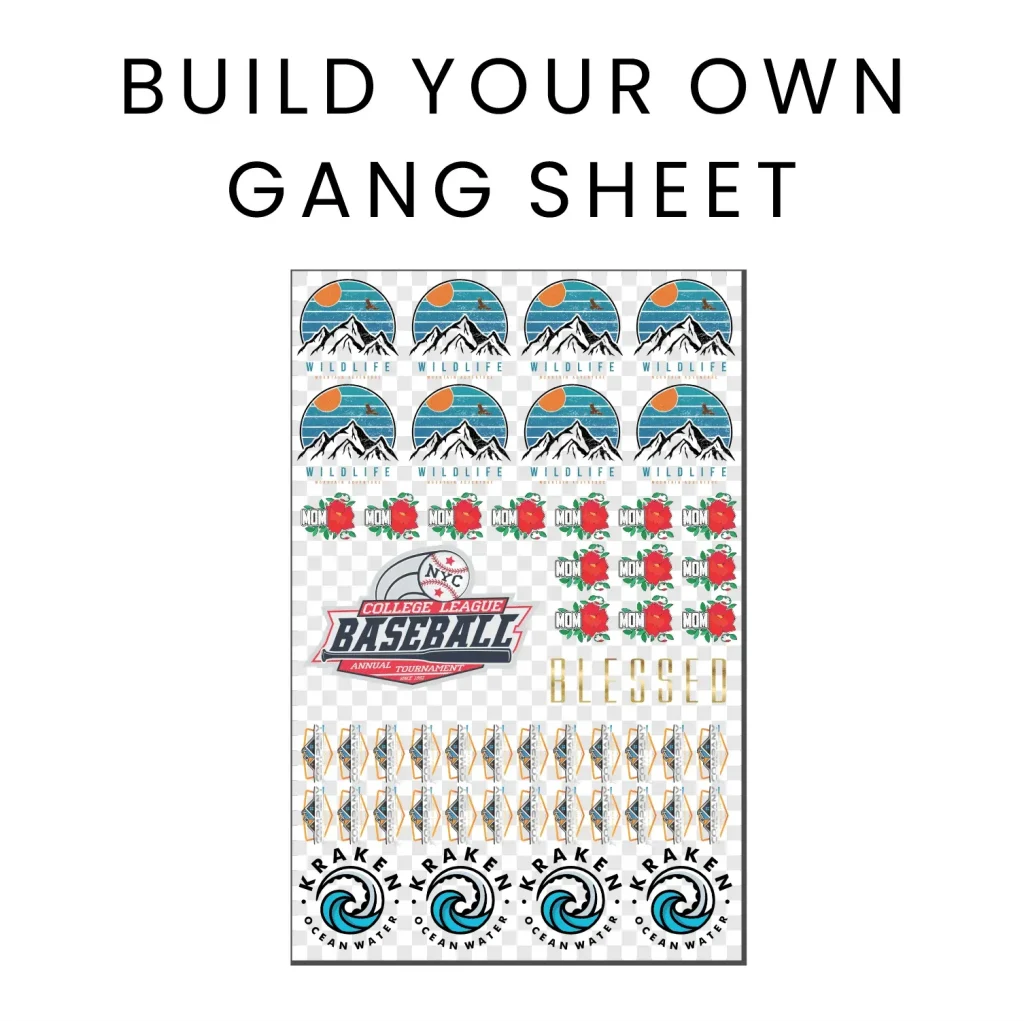

DTF gangsheet builder is a game-changer for modern apparel printers, delivering precise, production-friendly layouts on a single sheet. Its DTF gangsheet builder features and DTF printing software features empower both small shops and large studios with streamlined workflows, reliable color handling, and smart space utilization, aligning with DTF gang sheet software expectations. A strong solution integrates with design tools and RIPs to automate repetitive tasks and minimize misalignment, supporting gang sheet layout for DTF. By reducing material waste and speeding up setup, it directly contributes to DTF workflow optimization and faster turnaround times. Whether you run a boutique shop or a high-volume facility, this tool helps you maximize every sheet and deliver consistent transfers.

Viewed through an LSI lens, this kind of tool is a sheet-ganging platform that bundles multiple designs onto a single transfer sheet with smart spacing. Alternative terms you might encounter include multi-design layout optimizer, transfer sheet planner, or garment print nesting software—each focusing on efficiency, waste reduction, and consistent color. Essential features align with color management, automatic reflow, and batch processing, yet described in user-friendly terms that emphasize practical workflows. When teams discuss DTF workflow optimization, they are often describing the same capability from a slightly different semantic angle. Think of it as a production planner for transfer sheets that reduces waste and accelerates manufacturing, helping you scale without sacrificing quality.

1) Understanding the Value of a DTF gangsheet builder

In modern DTF production, the DTF gangsheet builder functions as the central organizer for your designs, turning scattered artwork into a cohesive, print-ready plan. By assembling multiple transfers onto a single sheet, it helps maximize each print run while preserving color integrity and registration. This descriptive overview highlights how a dedicated gangsheet tool supports faster decisions, less manual adjustment, and a smoother path from design to final transfer, which directly contributes to DTF workflow optimization.

A well-chosen DTF gangsheet builder integrates with your existing design tools and RIPs, automating repetitive tasks and enabling batch processing that would be impractical to perform by hand. With intelligent layout options and template-driven workflows, you can scale production without sacrificing accuracy or quality, making it easier to meet tight deadlines and maintain consistency across orders. In short, the right builder aligns creative freedom with production discipline for sustainable growth.

2) Key Features of a DTF Gangsheet Builder that Drive Efficiency

The most impactful features of a DTF gangsheet builder fall into two camps: intuitive layout capabilities and robust automation. An effective tool provides a flexible gang sheet layout with drag-and-drop placement, snap-to-grid alignment, and automatic spacing controls so you can optimize every sheet without risking overlaps. This directly supports the gang sheet layout for DTF, enabling precise nesting and batch adjustments that boost throughput.

Beyond layout, template libraries, color management, and seamless RIP integration turn a good tool into a production powerhouse. Template libraries speed up setup for common garment sizes and placements, while color-aware layouts minimize ink changes and save time. When paired with batch processing and reliable export options, these features constitute the core of what is often described as DTF gangsheet builder features, and they play a central role in real-world DTF workflow optimization.

3) Optimizing Gang Sheet Layout for DTF to Save Material

Optimizing the gang sheet layout for DTF is about density, margins, and intelligent nesting. By arranging designs to reduce empty space and by using sheets efficiently, you minimize waste and lower per-unit costs. The gang sheet layout for DTF should support irregular shapes and multi-color blocks, enabling operators to pack more transfers onto each sheet without compromising print quality.

Material-aware planning translates directly into tangible savings. A strong builder can calculate waste, suggest alternative placements, and automate reflow of designs to fit new layouts. This is at the heart of DTF workflow optimization, where small improvements in sheet density compound into quicker turnarounds, lower material costs, and more predictable production schedules.

4) Integrations that Streamline Production: Design Tools and RIPs

Seamless integration with design software (such as Illustrator or CorelDRAW) and RIPs is essential for maintaining a smooth, end-to-end workflow. The best DTF gang sheet software provides plugins, export formats, and direct integration that reduce file conversions and data loss. Such compatibility ensures that your designs stay faithful to the original while moving cleanly into the print pipeline.

A robust integration strategy minimizes touches and manual rework, letting operators focus on quality control rather than file preparation. With strong support for industry-standard formats and reliable metadata preservation, you gain a more reliable, repeatable process—an essential component of DTF printing software features that support consistent output and faster job turnovers.

5) Color Management and Print Quality with DTF Printing Software Features

Color management is a cornerstone of successful DTF production. A capable DTF printing software features robust color profiles, color-aware placement, and alignment guidance to ensure each transfer lands with expected hues and saturation. By coordinating color workflows within the gangsheet, you reduce ink waste and avoid color mismatches across designs.

In addition to color accuracy, print quality hinges on calibration tools, registration marks, and proofing capabilities. Regular color proofs and calibration help validate color accuracy before full production, preventing costly reprints. These capabilities are integral to DTF printing software features and contribute to reliable results when executing complex gang sheets.

6) Choosing, Trialing, and Scaling Your DTF Workflow with a Builder

Selecting a DTF gangsheet builder requires assessing current bottlenecks, such as layout time, color adjustments, or file prep. A practical approach is to trial the software with real orders to confirm it handles your typical garment sizes, colorways, and design complexity. Look for a balance of powerful features and approachable usability, plus clear documentation and responsive support.

To scale efficiently, ensure the tool supports multiple users, recurring job templates, and seamless data flow across your RIP and printers. Ongoing updates, training resources, and strong vendor support are critical for long-term success. When evaluating options, prioritize those that promote DTF workflow optimization, robust automation, and reliable integration into your existing production ecosystem—the hallmarks of a comprehensive DTF gangsheet builder.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it optimize the gang sheet layout for DTF production?

A DTF gangsheet builder is software that creates multi-design gang sheets on a single transfer. It offers a flexible gang sheet layout for DTF with drag-and-drop placement, snap-to-grid, and nesting to maximize sheet usage, minimize gaps, and speed setup, contributing to DTF workflow optimization.

Which DTF gangsheet builder features enhance color accuracy and align with DTF printing software features?

Key features include color management with ICC profiles and color-aware placement, integration with RIPs, and color proofs. These DTF printing software features help preserve color integrity across gang sheets and reduce color-related reworks.

How does batch processing in a DTF gangsheet builder boost production efficiency and workflow consistency?

Batch import and automatic reflow of designs to fit sheets let you process many orders in one pass. Rule-based constraints ensure margins, bleed, and color limits are respected, reducing manual edits and improving DTF workflow optimization.

What integration options should you expect from DTF gangsheet builder features with design tools and RIPs?

Look for plugins or direct export to Illustrator or CorelDRAW, plus seamless export formats and metadata preservation. Tight integration minimizes file conversions and preserves data, aligning with DTF gang sheet software workflows.

How can a DTF gangsheet builder help reduce material waste and improve sheet utilization?

A good builder optimizes sheet density, margins, and waste calculations, and offers templates for common sizes. This material waste reduction is a core part of DTF workflow optimization.

What export options and collaboration features are important in a DTF gangsheet builder for team production?

Robust export options, batch export, and multiple formats help teams stay compatible with their RIPs. User permissions, audit trails, and collaboration features support coordinated production in DTF gang sheet software environments.

| Feature Area | What it does | Why it matters |

|---|---|---|

| Intuitive gang sheet layout and grid management | Flexible layout engine with drag-and-drop, snap-to-grid, and support for irregular shapes, nesting, and precise spacing to prevent overlaps. | Enables precise, efficient packing of designs on a sheet, reducing layout time and errors. |

| Template libraries and reusable assets | Time-saving templates for common garment sizes, placements, and colorways that can be customized and saved for future jobs. | Ensures consistency, speeds setup for new orders, and scales production efficiently. |

| Batch processing and automation | Batch import, automated reflow of designs to fit sheets, and rule-based constraints (margins, bleed, color limitations). | Reduces manual effort and human error while increasing throughput for large runs. |

| Color management and color-aware layout | Color profiles and RIP integration; color-aware placement to group/rearrange by color to minimize ink changes and optimize print times. | Improves color accuracy and print efficiency by planning color usage. |

| Seamless integration with design tools and RIPs | Plugins and direct integration with popular design software (e.g., Illustrator, CorelDRAW) and RIP workflows; minimizes file conversions. | Smoother workflows with fewer data loss points and faster hand-offs. |

| Robust export options and file formats | Multiple export options, preserves metadata, and supports batch export for large runs. | Delivers ready-to-print files and eases production hand-offs. |

| Print-ready accuracy and registration guidance | Registration marks, calibration tools, and guidance to align layers accurately. | Ensures high-quality transfers with reliable registration on garments. |

| Material waste reduction and material-aware planning | Optimizes sheet density, margins, and waste calculation to lower material costs. | Cuts waste and production costs while maximizing sheet use. |

| User permissions and collaboration features | Role-based access, audit trails, and collaborative features for teams. | Supports teamwork in production environments with accountability and traceability. |

| Easy updates and ongoing support | Regular updates, responsive support, and clear documentation. | Keeps tools current and minimizes downtime during transitions. |

Summary

Conclusion: A DTF gangsheet builder is a powerful ally in modern DTF production. By prioritizing features like intelligent layout, batch processing, color management, and seamless integration with RIPs and design tools, you can achieve significant gains in efficiency, accuracy, and throughput. Whether operating a small shop or a larger facility, an effective gangsheet builder helps maximize every sheet, reduce waste, and deliver high-quality transfers faster. Start with the featured capabilities, test with real jobs, and choose a solution that offers solid support and room to grow for future production needs.