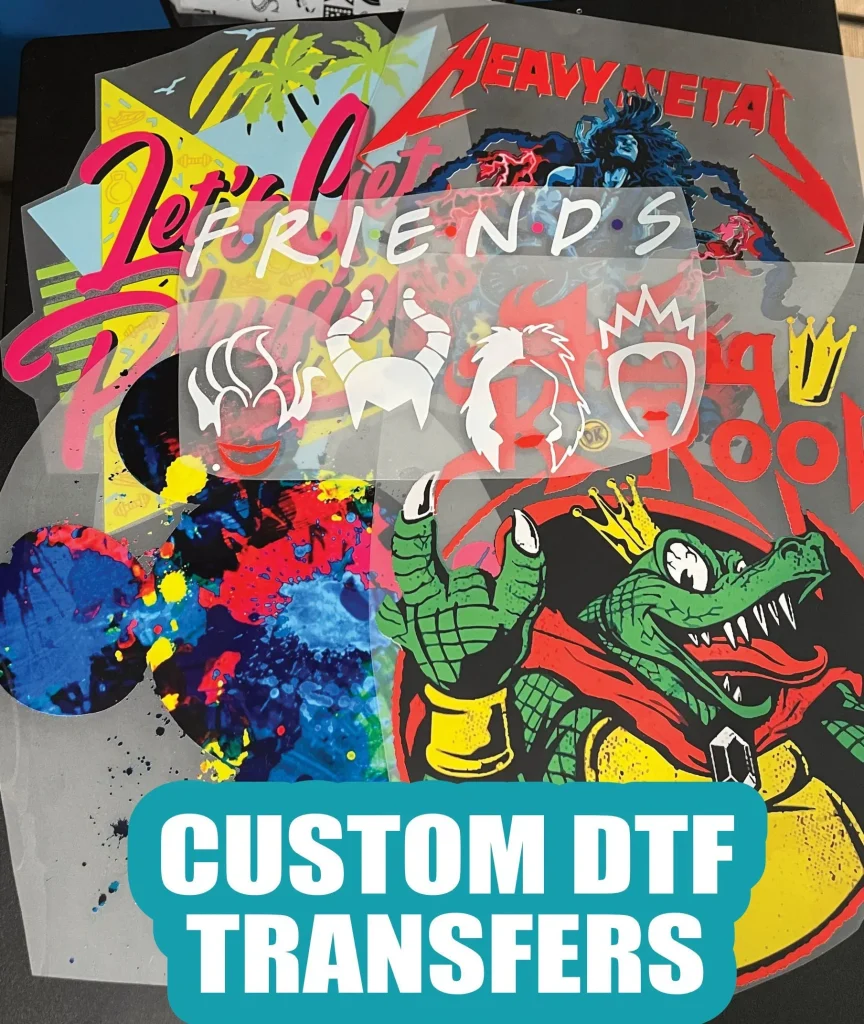

DTF transfers, or Direct-to-Film transfers, are transforming the landscape of custom T-shirt printing by offering a seamless and efficient method for applying vibrant designs to fabric. As this innovative technology becomes increasingly accessible, printers and designers alike are turning to DTF printing for its impressive durability and versatility across various materials. DTF allows for intricate designs that stand out, capturing attention while withstanding the test of time through numerous washes. For small business owners and crafting enthusiasts, mastering the DTF transfer process unlocks a world of creative possibilities and market opportunities. This guide explores everything you need to know about DTF transfers, empowering you to elevate your garment printing capabilities.

Direct-to-Film transfers, known within the garment printing industry as DTF printing, represent a modernized approach to design application that surpasses traditional methods. Many refer to this technique as a game-changer for individuals and businesses seeking to create custom apparel quickly and effectively. By focusing on high-quality prints that can be just as intricate as screen printing or sublimation, DTF technology emphasizes ease of use and broad fabric compatibility. The emergence of platforms like Snuggle DTF highlights the growing recognition of this innovative system within the T-shirt printing realm. Understanding these alternative terms and their implications is key to leveraging the full potential of DTF for your personalized garment projects.

Understanding DTF Printing Process

The DTF printing process represents a significant evolution in the realm of T-shirt production. By first printing an image onto a specialized film and then adhering it to fabric using heat and adhesive, it allows for vibrant output with intricate detail. The versatility of DTF transfers extends their applicability across a variety of materials such as cotton, cotton-poly blends, and synthetic fabrics. This means that users can produce high-quality custom T-shirts that cater to diverse customer demands.

Moreover, DTF is structured to achieve excellent color reproduction and durability, which are crucial factors for clothing that will undergo frequent washing. As users delve into DTF printing, they often discover that this method not only enhances productivity in their operations but also opens a new landscape of creative possibilities for custom graphic designs.

The Advantages of DTF Transfers

DTF transfers boast several advantages that firmly place them ahead of conventional printing methods. The most notable is their fabric compatibility; DTF can be used on numerous surfaces, including those that traditional methods might struggle with, such as dark or textured fabrics. This gives designers and business owners the freedom to explore a broader range of materials without the worry of compromising quality.

Durability is another critical advantage of DTF. The prints are resilient against fading, peeling, and cracking even after repeated washing cycles. This makes DTF transfers an optimal choice for producing long-lasting custom T-shirts that retain their charm and vibrancy over time, appealing to both consumers and producers.

How DTF Transfers Compare to Other Printing Techniques

When evaluating printing methods, DTF transfers often come out on top in various respects. Unlike sublimation printing, which typically limits designs to polyester fabrics, DTF can be applied to a range of materials including cotton and blends. This versatility not only increases production opportunities but also enhances market reach for small businesses aiming to diversify their product lines.

Additionally, the quality of color output is another area where DTF transfers excel. The capability to effectively reproduce detailed graphics in vibrant hues enables designers to create eye-catching custom T-shirts that stand out in an increasingly competitive market. Customers tend to value the bold aesthetic that these prints provide, often leading to increased sales for businesses.

Getting Started with DTF Printing

Beginning your journey with DTF printing involves several crucial steps. The first is choosing reliable equipment; investing in a quality DTF printer is non-negotiable if you desire vibrant and durable prints. Make sure your chosen printer is compatible with the specific DTF films and inks to ensure optimal performance.

Once you have the equipment set up, it’s time to experiment with various transfer films and adhesives that cater specifically to DTF processes. This initial phase of mastering the DTF transfer technique is instrumental in achieving consistent results. By familiarizing yourself with heat settings and experimenting with different types of fabrics, you’ll be well on your way to producing exceptional custom T-shirts that resonate with your audience.

Current Trends in Custom T-Shirt Printing

The landscape of custom T-shirt printing is continuously evolving, and DTF technology has emerged as a frontrunner in this dynamic market. Many small business owners and hobbyists are gravitating toward this printing method, drawn by its simplicity and the unique design capabilities it affords. The ability to quickly adapt to market trends by producing immediate, custom designs is becoming increasingly vital.

Furthermore, the growth of online platforms and communities focusing on DTF printing has made this technology more accessible to newcomers. With shared resources and best practices circulating widely, many individuals are finding success in launching their custom apparel businesses, leading to a flourishing sector that integrates creativity with technology.

Exploring DTF Design Options

DTF printing allows for a creative exploration that can elevate standard T-shirt designs into something extraordinary. By enabling intricate images, logos, and patterns, designers harness the power of graphic design software to create visually stunning graphics tailored for various audiences. This level of customization helps brands express unique identities while standing out in a crowded marketplace.

Additionally, as trends in graphic design evolve, DTF technology provides the flexibility to keep pace with changing consumer preferences. The swift turnaround time and effective production capabilities of DTF transfers empower businesses to launch limited edition designs or seasonal collections quickly, maintaining relevance and interaction within their target communities.

Navigating the Future of DTF Transfers in Apparel

As DTF transfers continue to gain traction, it is evident that they are shaping the future of apparel printing. The ongoing improvements in technology, alongside a surge in customizable options, indicates an exciting period ahead for both manufacturers and consumers. With the introduction of platforms like Snuggle DTF streamlining the process, the ability for businesses to integrate DTF technology is becoming more feasible.

The focus on sustainability within the printing sector is also influencing DTF trends, as more companies seek eco-friendly practices without sacrificing quality. As awareness around sustainable production increases, DTF’s capacity to produce minimal waste while ensuring high-quality output positions it as a leading choice for responsible garment printing. The future of custom T-shirts and DTF technology is undoubtedly bright.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special plastic film. After the design is printed, an adhesive is added, and the film is heat-pressed onto fabric. This method allows for vibrant and durable prints suitable for various materials, making it a popular choice for custom T-shirt printing.

How do DTF printing and traditional methods compare?

DTF printing offers advantages over traditional methods like sublimation by being compatible with a wider range of fabrics, including cotton and blends. Additionally, DTF transfers maintain their vibrancy after multiple washes, providing cost-effective solutions for both small and large print runs.

What equipment is needed for DTF T-shirt printing?

To start DTF T-shirt printing, you’ll need a high-quality DTF printer, special transfer films designed for the DTF process, and a reliable heat press. Investing in quality equipment ensures that your DTF transfers produce vibrant and long-lasting designs.

Why are DTF transfers gaining popularity?

DTF transfers are gaining popularity due to their versatility, ease of use, and rapid production times. They allow for intricate designs that cater to the growing demand for custom T-shirts, making them an ideal choice for both small business owners and DIY enthusiasts.

What types of fabrics can DTF transfers be applied to?

DTF transfers are compatible with a wide variety of fabrics, including cotton, polyester, and blends. This versatility makes DTF a preferred option for garment printing, allowing creators to experiment with different types of apparel.

How can I get started with DTF transfers for T-shirt printing?

To get started with DTF transfers, invest in quality printing equipment, choose compatible transfer films, and learn the heat press techniques required for optimal application. Additionally, explore design software to create unique graphics that can be printed using DTF technology.

| Key Points | Details |

|---|---|

| What is DTF? | DTF printing involves printing designs onto a special plastic film, applying adhesive, and heat pressing it onto fabric. |

| Recent Developments | The launch of the Snuggle DTF platform has made DTF technology more accessible for commercial providers. |

| Advantages | 1. Versatility with various fabrics 2. High durability 3. Vibrant colors 4. Cost-effective for all production sizes |

| Benefits | 1. Wide fabric compatibility 2. Ease of use 3. Rapid turnaround |

| User Trends | DTF is favored by small business owners for its ease of application and quick production of unique designs. |

| Getting Started Tips | 1. Invest in quality equipment 2. Select compatible films 3. Master the transfer process 4. Explore design options 5. Stay updated on trends. |

Summary

DTF transfers represent a groundbreaking advancement in T-shirt printing technology, providing an efficient means of applying vibrant and durable designs to a diverse array of fabrics. This innovative method not only caters to a variety of materials but also enhances the creative potential for businesses and crafters alike. With the emergence of user-friendly platforms such as Snuggle DTF, accessing and mastering DTF transfers has never been easier, making it an essential technique for those looking to thrive in the custom apparel market. By understanding the intricacies of DTF printing, users are better equipped to capitalize on the growing demand for unique, high-quality printed garments.