DTF transfers, or Direct to Film transfers, are revolutionizing the landscape of digital apparel printing, offering a dynamic and efficient way to create custom designs. This modern printing technique allows for crisp, vibrant images that adhere to a variety of fabric types, making it an ideal choice for both personal projects and business applications. If you are eager to learn how to use DTF transfers, you’ve landed in the right place! In this guide, we’ll delve into the DTF printing process, highlighting the advantages of DTF transfers, and offering a comprehensive overview to help you get started with digital apparel printing. Embrace the future of clothing design where creativity knows no bounds and the possibilities are endless!

DTF printing, often referred to as Direct to Film printing, harnesses the power of innovative technology to transfer vibrant custom images onto fabrics. This technique stands out in the realm of digital garment printing, making it easier and more efficient for enthusiasts and professionals alike to craft unique apparel. Whether you’re looking to create personalized clothing or focus on larger production runs, understanding the DTF printing process is essential. The DTF approach not only ensures superior print quality but also offers flexibility with various textiles, catering to an array of design preferences. As we explore how this modern method reshapes custom clothing creation, prepare to be inspired by its benefits and practical applications.

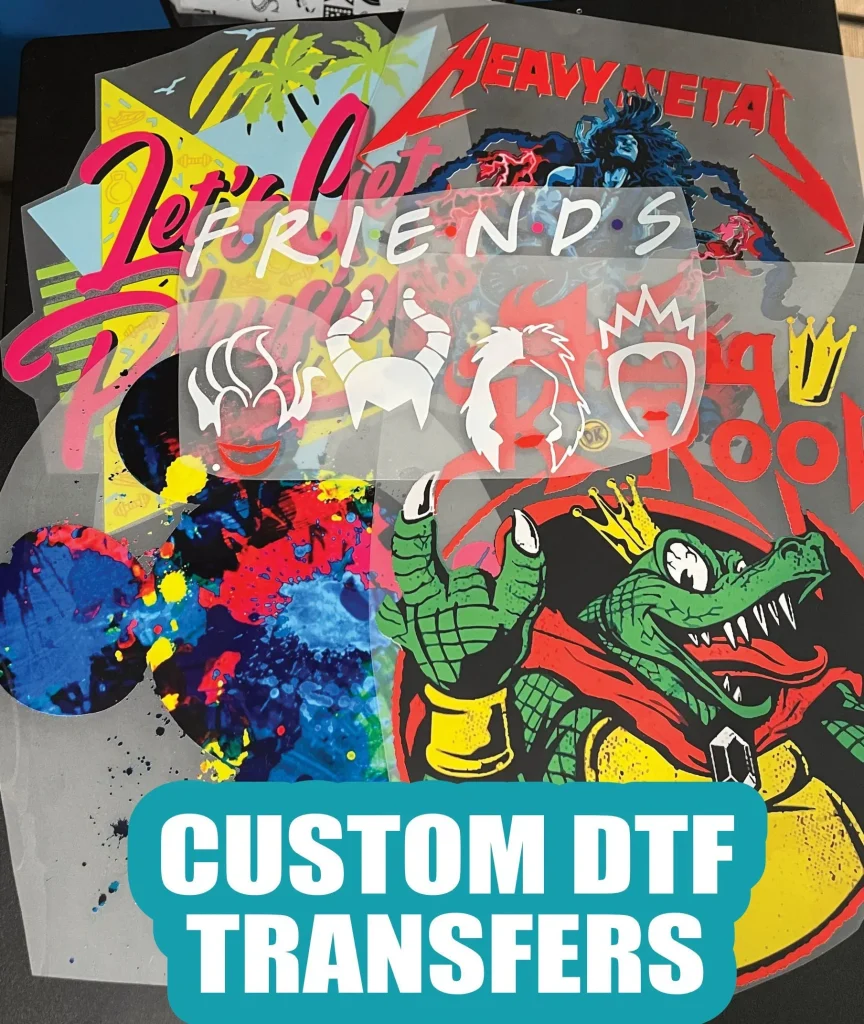

Understanding DTF Transfers: A Modern Printing Technique

DTF transfers, or Direct to Film transfers, represent a significant advancement in the apparel printing industry. This innovative technique not only offers high-quality images but also seamlessly adheres to a variety of fabric types, making it a versatile choice for custom apparel printing. The process uses specially formulated inks and a meticulously engineered transfer film, ensuring that designs remain vibrant and durable, even after multiple washes. As one delves deeper into the specifics of DTF transfers, it becomes evident that the meticulous layering of ink and adhesive powder plays a crucial role in achieving professional results.

In contrast to traditional fabric printing methods, DTF transfers allow for enhanced creativity and detail in designs. Whether you’re looking to produce apparel for a small boutique or train your team for a corporate event, the ability to create intricate designs that apply uniformly across different textiles is a game-changer. This flexibility has made DTF the go-to method for digital apparel printing, especially for those seeking to create unique, customized pieces that stand out.

The Intricate DTF Printing Process: Step-by-Step Guide

The DTF printing process can be broken down into clear, manageable steps that anyone can follow with the right equipment. Initially, it starts with design creation, where graphics software is utilized to produce eye-catching artworks. This step lays the foundation for everything that follows; the quality of your design is pivotal in ensuring a successful transfer. Once your design is ready, it is printed on a DTF transfer film, which requires a specialized inkjet printer that utilizes DTF inks to achieve those bold, rich colors we expect from high-end apparel.

Next, the application of adhesive powder to the printed film is essential for ensuring the design clings properly to the desired fabric. After sprinkling the powder onto the film, the mixture is cured with heat, creating a bond that will hold the transfer together upon pressing. The final act involves using a heat press to adhere this masterpiece to the garment of choice; this part of the process brings together every element that you’ve worked on previously, allowing you to see a tangible, finished product.

Advantages of DTF Transfers in Custom Apparel Printing

One of the standout benefits of DTF transfers is the vibrant and long-lasting nature of the prints. Unlike some other traditional methods that may render dull results, DTF prints are known for their sharp contrast and vivid color applications. This is particularly advantageous in the custom apparel sector, where vivid imagery can significantly influence a buyer’s decision. Furthermore, the durability of DTF prints means that clothing items designed with this process maintain their appearance even after numerous washes, providing excellent value for both creators and consumers.

Moreover, DTF transfers are highly versatile, fitting a myriad of fabrics ranging from cotton and polyester to blends. Such wide-ranging compatibility allows businesses to cater to various markets without needing to invest in multiple printing methods. This adaptability not only expands the creative options available but also streamlines production processes, making it easier for print shops to manage inventory and fulfill unique orders efficiently.

Essential Equipment for DTF Transfers: What You Need

To successfully embrace DTF printing, a few essential pieces of equipment are non-negotiable. First and foremost, you will need a DTF printer specifically configured for this type of transfer. A standard inkjet printer won’t suffice; modified printers designed to handle DTF inks are crucial for achieving those stunning, rich prints. Additionally, high-quality DTF transfer films are vital, as they directly influence the clarity and durability of your final product.

An equally important component is the adhesive powder, which is the secret ingredient that ensures the design sticks to the fabric during the heat press application. Finally, investing in a reliable heat press machine is essential for this process. A quality heat press will provide the necessary temperature and pressure settings that are critical for perfecting your DTF transfers, thereby ensuring that every print adheres to the fabric smoothly and securely.

A Step-by-Step Guide to Mastering DTF Printing

Mastering the DTF printing process involves executing a systematic approach, starting from design creation to the final heat application. For beginners, it’s essential to begin with familiar graphic design software that allows you to create designs tailored to specific garments. Understanding the dimensions of the piece being printed ensures that your artwork fits perfectly upon transfer, which is crucial for a professional finish.

Once your design is prepared, printing on the DTF film is the next critical step. Remember to load the film correctly into your printer, often in a mirrored format to ensure a flawless transfer. Then, after applying the adhesive powder and curing it appropriately, the actual heat press procedure is where the magic happens. Correct temperature settings and timing are paramount; allow the design to bond to the garment fully before peeling the transfer film away to reveal a beautifully printed design.

Cost Considerations for Starting DTF Printing Ventures

While DTF printing offers numerous advantages, it’s important to address the financial aspect of getting started. The initial investment can be significant, especially for high-quality printers and other essential equipment. However, savvy entrepreneurs recognize this investment as a stepping stone towards more efficient production capabilities and increased profit potential, particularly as demand for custom apparel continues to rise.

Beyond the upfront costs, prospective DTF printers must also factor in the ongoing expenses, such as purchasing high-quality transfer films and adhesive powders. Despite the initial costs, many find that cost-effectiveness increases over time due to the lower consumption of materials and the ability to manage smaller orders efficiently without sacrificing quality. By carefully planning and budgeting for these variables, it’s possible to carve a niche in the competitive custom apparel market.

Frequently Asked Questions

What are DTF transfers and how do they work in digital apparel printing?

DTF transfers, or Direct to Film transfers, use a specialized printing technique to transfer images onto fabric. The process involves creating a digital design, printing it onto transfer film using DTF inks, applying adhesive powder, and finally using a heat press to bond the design to the garment. This method allows vibrant colors and intricate details, making it a popular choice for custom apparel printing.

What are the advantages of using DTF transfers for custom apparel printing?

DTF transfers offer several advantages for custom apparel printing, including vibrant prints that are durable and long-lasting. They work on a variety of materials, from cotton to polyester blends, making them versatile. DTF printing is also cost-effective over time, as it minimizes ink use and can accommodate orders of any size, whether you need just one shirt or a hundred.

How can I get started with DTF transfers for my business?

To get started with DTF transfers, you’ll need a modified inkjet printer, high-quality DTF transfer films, adhesive powder, and a heat press machine. Create your design using graphic software, then print it onto the transfer film and apply the adhesive. Finally, use the heat press to transfer the design onto the fabric. This process allows you to produce custom apparel efficiently.

What is the DTF printing process step-by-step?

The DTF printing process involves several key steps: 1) Create your design using graphic software; 2) Print the design on DTF transfer film with specialized inks; 3) Apply adhesive powder while the print is hot; 4) Cure the adhesive with heat; 5) Use a heat press to transfer the design onto the fabric. Each step is crucial for achieving high-quality, durable prints.

Are there any special considerations when using DTF transfers for printing?

Yes, when using DTF transfers, consider the startup costs for equipment like printers and heat presses, which can be significant. Additionally, there’s a learning curve involved in mastering the process and achieving optimal results. Practice and experimentation are essential to refine your skills and maximize the effectiveness of DTF printing.

Can DTF transfers be used on any fabric?

DTF transfers are highly versatile and can be applied to a wide range of fabrics, including cotton, polyester, and blends. Unlike some traditional printing techniques, DTF does not have strict limitations on fabric types, making it a suitable option for various custom apparel projects.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | Modern printing technique for transferring images onto fabrics using inks, films, and adhesive powders. |

| The DTF Printing Process | 1. Design Creation 2. Printing on Film 3. Applying Adhesive Powder 4. Heat Press Application |

| Advantages of DTF Transfers | – Vibrant Prints – Versatile Material Compatibility – Cost-Effective Over Time – No Minimum Quantity Needed |

| Getting Started | Equipment Needed: DTF Printer, Transfer Film, Adhesive Powder, Heat Press Machine |

| Step-by-Step Guide | 1. Create Design 2. Print Design 3. Apply Adhesive Powder 4. Heat Press 5. Peel and Inspect |

| Considerations | – Startup Costs – Learning Curve |

Summary

DTF transfers represent a pioneering method in digital apparel printing, showcasing vibrant colors and impressive versatility across various fabrics. By utilizing a series of simple yet effective steps from design creation to heat pressing, anyone can tap into the potential of this innovative printing method. As the market for custom apparel continues to grow, DTF transfers stand out due to their cost-effectiveness and adaptability, making them an ideal choice for both casual creators and aspiring entrepreneurs alike.