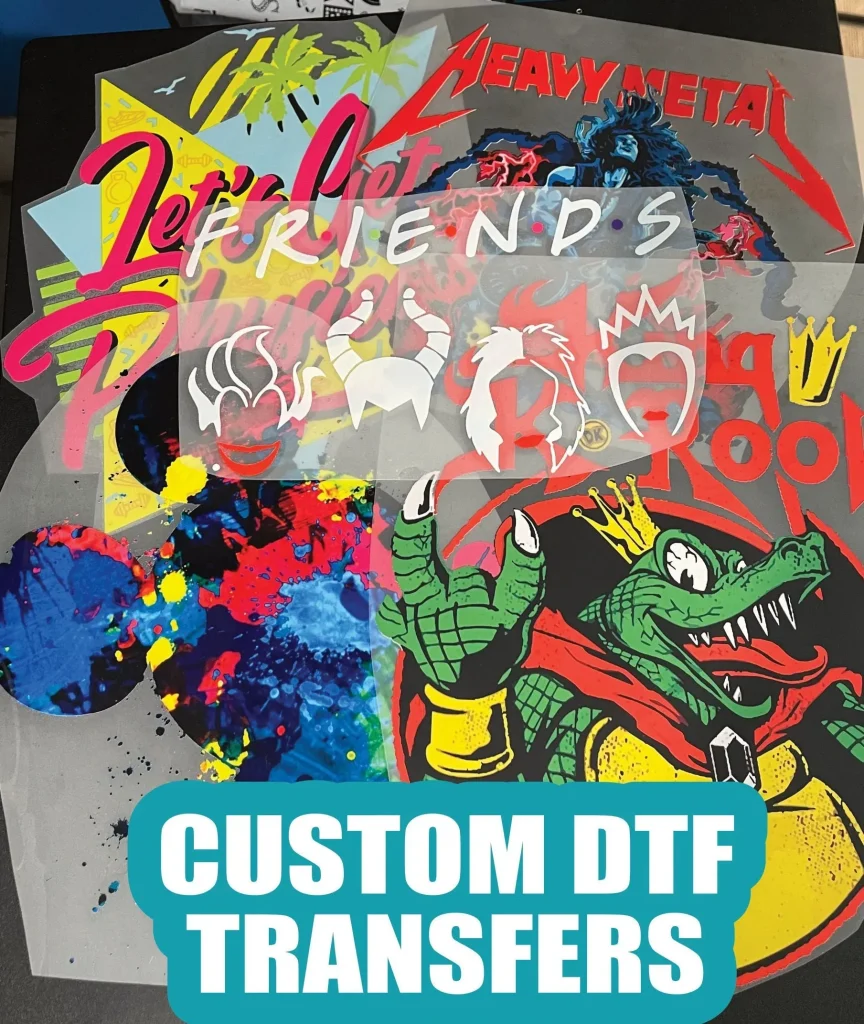

DTF transfers, short for Direct to Film transfers, represent a groundbreaking leap in the printing industry, combining efficiency with high-quality output. This innovative technology allows for vibrant designs to be printed directly onto films before they are transferred onto various fabrics, creating stunning results that cater to the custom apparel market. With DTF printing advantages such as lower setup costs and faster turnaround times, it’s no wonder that businesses and creatives alike are turning to this method for their print on demand needs. As we delve deeper into DTF transfer technology, we’ll uncover how it’s reshaping custom apparel printing and why it’s becoming a preferred choice for entrepreneurs. Join us as we explore the transformative capabilities of DTF transfers and their impact on the future of printing.

Direct to Film (DTF) printing technology is rapidly becoming a go-to solution for individuals and businesses looking to enhance their printing capabilities. By utilizing advanced film preparation, this method effectively bridges the gap between traditional printing techniques and modern customization demands. The benefits of utilizing DTF methods include not only exceptional print clarity but also the ability to produce unique designs on-demand, thus appealing to a wide range of customers. Particularly in the realm of custom apparel, DTF printing’s flexibility and efficiency are unparalleled, allowing creators to swiftly respond to market trends and customer preferences. As the landscape of printing continues to evolve, the importance of DTF technology cannot be overstated.

The Evolution of DTF Printing Technology

The evolution of Direct to Film (DTF) printing technology marks a pivotal shift in the printing industry landscape. Established only recently, DTF printing has quickly become a preferred choice for many due to its innovative approach to design application. This technology utilizes a specialized film that captures intricate designs and can transfer them onto a variety of substrates, including textiles and more. As printing needs evolve, DTF technology provides solutions that are not only efficient but also enable greater creativity.

Modern advancements in DTF transfers have enhanced print quality and production speed. With ongoing research and development, we see increased resolution, vibrant colors, and improved durability of prints. This evolution demonstrates that as technology progresses, businesses must adapt their practices to utilize these enhancements for maximizing their output while providing superior products.

Advantages of DTF Transfers Over Traditional Methods

DTF transfers come with an array of advantages that distinguish them from traditional screen printing methods. One of the most notable benefits is cost-effectiveness; DTF printing requires lower setup costs, making it an economically viable option, especially for small production runs. This allows businesses to offer competitive pricing while maintaining quality, ultimately boosting profit margins.

Furthermore, DTF transfers accommodate a broader range of design options. Unlike screen printing, which often requires more time and resources for intricate designs, DTF allows for complex and colorful images to be replicated seamlessly on garments. This flexibility is particularly advantageous in the realm of custom apparel printing, where personalization is key to attracting customers.

DTF Printing for Custom Apparel

Custom apparel has seen a remarkable transformation with the adoption of DTF printing technology. By enabling precise design transfers onto fabrics, DTF makes it easier for businesses to cater to individual customer preferences. This customization is not only appealing but can also establish a stronger connection between brands and their clientele.

Moreover, DTF printing excels at producing high-resolution images, ensuring that even the most intricate designs are rendered beautifully on fabrics. As a result, businesses venturing into the custom apparel market can confidently offer unique products that stand out from mass-produced items, enhancing their branding and market appeal.

Navigating the Print-On-Demand Market with DTF

As the print-on-demand industry continues to flourish, DTF technology plays a critical role in shaping its future. The ability to print designs on demand without the need for large inventories reduces waste and supports sustainable business practices. DTF transfers are not only efficient but also cater seamlessly to the fluctuating demands of customers looking for personalized items.

With high-quality output and rapid production times, DTF printing delivers the speed required in today’s fast-paced market. Entrepreneurs can leverage this technology to stay ahead of trends while meeting customer expectations for timely delivery of customized products. Thus, DTF serves as a fundamental tool for success in the evolving print-on-demand landscape.

Recent Innovations in DTF Technology

Recent innovations in DTF technology are expanding the boundaries of what’s possible in the printing industry. Companies are consistently investing in new machinery and optimized processes to enhance the quality and efficiency of DTF transfers. For instance, new roll-to-roll systems have been developed, allowing for streamlined production and increased output volume.

These advancements not only improve operational efficiency but also ensure that businesses can offer a wider range of products with customization options that appeal to consumers. As technology continues to progress, staying up-to-date with these innovations will be crucial for businesses looking to leverage DTF printing to its full potential.

The Future of DTF Printing and Market Trends

The future of DTF printing looks promising as market trends indicate a continued shift toward digital solutions in the printing industry. Events like the upcoming DTF Expo 2025 are set to highlight these advancements and foster networking opportunities for professionals eager to explore the potential of DTF technology.

As businesses increasingly prioritize sustainability, efficiency, and versatility, DTF printing will undoubtedly solidify its position as a leading method for custom applications. By adapting to these changing market dynamics, businesses can capitalize on the benefits of DTF transfers to meet the growing demand for innovative and personalized products.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film transfers, involve printing designs onto a specialized film, which is then applied to fabric using heat and pressure. This method allows for high-quality, durable designs that adhere well to various materials, making it a versatile choice for custom apparel printing.

What are the main advantages of DTF printing compared to traditional methods?

DTF printing advantages include cost-effectiveness, particularly for small runs due to lower setup costs, high-resolution output for vibrant and enduring designs, and faster turnaround times due to advancements in technology. These benefits make DTF transfers an ideal choice for businesses in the print on demand DTF market.

Can DTF transfer technology be used for all types of fabrics?

Yes, DTF transfer technology is compatible with a wide variety of fabrics, including cotton, polyester, and blends. This versatility allows businesses to cater to different customer preferences and expand their offerings in the custom apparel printing sector.

How do I integrate DTF transfers into my existing printing services?

To integrate DTF transfers, consider investing in a DTF printer, like an A3 model for smaller operations. Training staff on the DTF printing process and promoting new custom designs can help your business leverage this technology effectively.

What recent developments are impacting DTF transfers?

Recent developments in DTF transfers include increased production capacities, such as Snuggle’s new trade service for high-volume production, and significant infrastructure investments by companies like Eazydtf. These advancements improve efficiency and accessibility in the DTF printing industry.

What does the future hold for DTF printing technology?

The future of DTF printing technology looks promising, with upcoming innovations such as expanded color gamuts and roll-to-roll printing expected to enhance print quality and efficiency. Industry events like the DTF Expo 2025 will further drive trends and opportunities in custom apparel and merchandise.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers use advanced printing technologies to apply designs to fabrics and other substrates quickly and efficiently. |

| Printing Process | Involves printing a design on a specialized film that adheres to the substrate through heat and pressure, providing durability and vibrant colors. |

| Recent Developments | Companies like Snuggle and Eazydtf are expanding services and investing in infrastructure to enhance DTF printing capabilities. |

| Market Accessibility | New A3 printers make DTF technology more accessible for small businesses and entrepreneurs, fostering innovation. |

| Technological Advancements | Latest technologies promise improved efficiency, color range, and automation, enhancing print quality and customization. |

| Market Trends | The DTF printing industry is poised for growth, with events like DTF Expo 2025 spotlighting innovation and networking opportunities. |

| Benefits of DTF Transfers | Cost-effective, high-quality, customizable, and quicker turnaround compared to traditional methods. |

Summary

DTF Transfers represent a groundbreaking advancement in the printing industry, highlighting their potential to transform how designs are applied to various materials. With the evolution of Direct to Film technology, businesses can enjoy cost-effective and high-quality printing solutions that cater to a variety of customization needs. As market accessibility improves and technological innovations continue to emerge, DTF Transfers are set to become a dominant force, enabling entrepreneurs and established companies alike to enhance their printing capabilities and stay competitive in the dynamic landscape of custom apparel and merchandise.