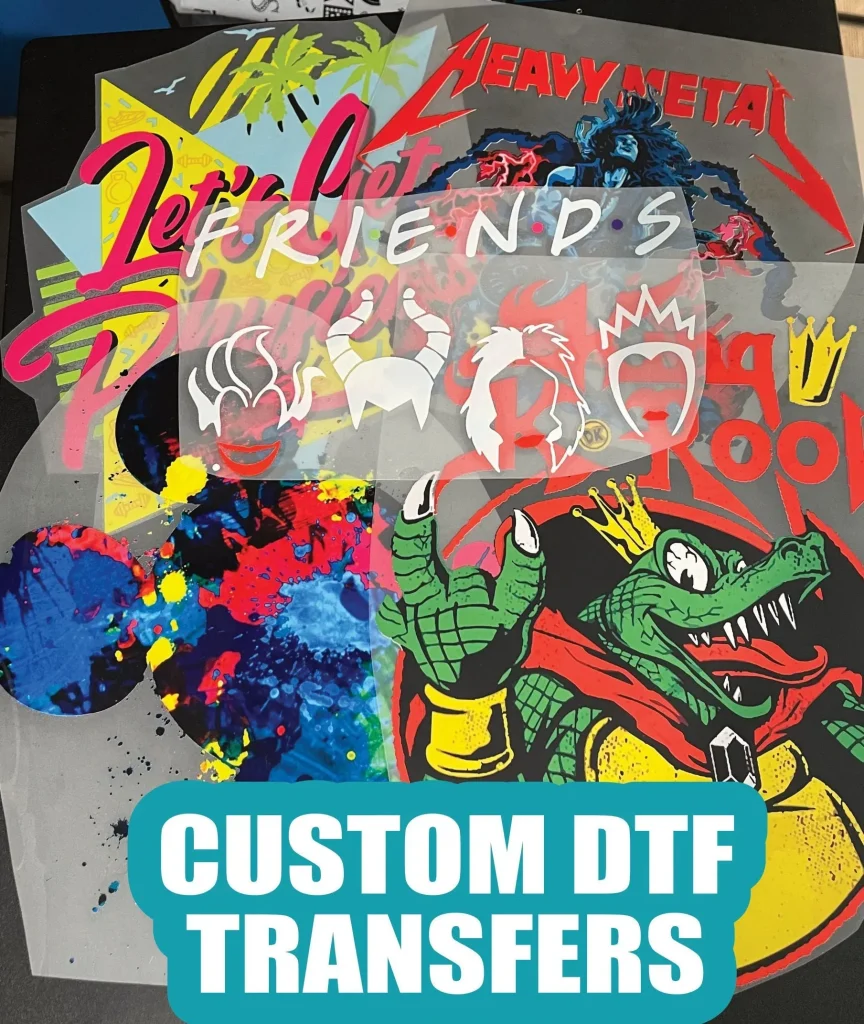

DTF Transfers have taken the custom apparel printing industry by storm, offering a cutting-edge solution for both professionals and DIY enthusiasts alike. With Direct-to-Film printing, the possibilities for vibrant colors and complex designs on various fabrics are truly limitless. This innovative DTF printing technology allows for seamless integration into print on demand DTF operations, enabling creators to deliver high-quality products with remarkable efficiency. As the demand for custom apparel printing continues to surge, businesses can leverage DTF printing services to stand out in a competitive market. In this blog post, we will delve into the advancements in DTF technology and explore how these enhancements can elevate your printing experience to new heights.

Exploring alternatives to traditional printing processes has become essential in today’s fast-paced market, and Direct-to-Film transfers represent a significant leap forward. Known for their versatility, these film-based printing methods provide impactful results on diverse textile materials. As custom design options expand, businesses can now utilize DTF printing capabilities with greater ease and speed, turning creative ideas into reality. By adopting this advanced printing technology, entrepreneurs and hobbyists can offer tailored solutions that meet customer demands, all while enjoying a more efficient production process. Join us as we navigate the transformative realm of film printing and its implications for the future of custom apparel.

The Rise of DTF Printing in Custom Apparel

In recent years, DTF printing has emerged as a game-changer in the custom apparel world, allowing creators to explore new realms of design with unprecedented ease. This technique, which stands for Direct-to-Film printing, utilizes cutting-edge equipment to produce high-quality transfers that can be applied to various fabrics. As this technology gains traction, it has opened up new avenues for hobbyists and small startups to engage in custom apparel printing without the steep learning curve traditionally associated with other methods.

One of the most appealing aspects of DTF printing is its versatility. Designers can experiment with a broad spectrum of materials, allowing for a diverse range of products including t-shirts, hoodies, and bags. The ability to print vibrant colors and intricate designs on cotton, polyester, and even blends makes DTF an attractive option compared to other printing methods. Furthermore, as more businesses adopt DTF processes, the market for custom apparel printing is primed for growth, providing exciting prospects for entrepreneurs and DIY enthusiasts alike.

DTF Transfers: The Future of Fabric Customization

DTF transfers are leading the charge in the evolution of fabric customization, thanks to their superior quality and durability in comparison to traditional methods. With stresses on a global scale for more sustainable and efficient printing solutions, DTF technology provides an eco-friendly option. This is particularly beneficial for small businesses aiming to make a mark in the saturated market of custom apparel. By using DTF transfers, creators can not only ensure a longer lifespan for their prints but also embrace a method that minimizes waste.

As demand grows, advancements in DTF printing services continue to emerge, allowing for increased production efficiencies. With innovations like high-speed large format printers, businesses can produce intricate designs at a fraction of the time it would take using conventional methods. DTF transfers not only cater to the need for speed but also uphold quality, making them a go-to solution for those looking to provide stellar customization services.

Comparing DTF to Traditional Sublimation Printing

The debate between DTF printing and sublimation printing is an essential conversation among custom apparel enthusiasts. While both methods have unique benefits, DTF printing distinguishes itself with its ability to adhere to a variety of fabrics, including cotton and blends that sublimation often struggles with. Sublimation requires a specific polyester base to achieve vibrant results, limiting its applicability and versatility.

On the other hand, DTF printing capitalizes on vibrant colors and sharp design precision, making it an excellent choice for custom apparel that demands attention. This flexibility not only allows for a wider range of products but also enables crafters to unleash their creativity without the constraints associated with sublimation, ultimately reshaping how custom designs are perceived and produced in the marketplace.

Innovations in DTF Printing Technology

Recent innovations in DTF printing technology have vastly improved the quality and efficiency of print processes. Major brands like EazyDTF and DTFPrinter are investing in cutting-edge equipment that enhances the capabilities of Direct-to-Film printing. These advancements include higher resolution printers and faster drying inks, which collectively contribute to a more robust and reliable service for creators and small businesses alike.

Moreover, the introduction of user-friendly interfaces and automated systems streamlines the print-on-demand DTF process, making it easier for even novice users to produce professional-quality items. As the DTF industry continues to grow, ongoing research and development will undoubtedly usher in even more impressive advancements, solidifying its place in the custom printing landscape.

EazyDTF’s Pioneering Production Capacity Expansion

EazyDTF’s recent expansion of production capacity represents a significant leap in the DTF printing industry. By integrating ten new large format printers, they are not only increasing their output capabilities but also reducing turnaround times for customers. This move highlights the rising demand for high-quality DTF transfers, as more businesses and individuals recognize the advantages of this innovative printing method.

With the capability for same-day shipping, EazyDTF is setting new standards for customer service in the custom apparel printing market. They are positioning themselves as a leading provider of DTF printing services, ensuring that artists and entrepreneurs have access to the materials they need when they need them. This commitment to efficiency cultivates a vibrant community of makers who rely on DTF products for their creative endeavors.

Snuggle DTF: The New Web-to-Print Solution

Snuggle DTF’s recent introduction of a web-to-print platform signifies a transformative shift in how businesses approach custom apparel. By allowing users to easily upload designs and manage orders online, Snuggle is streamlining the DTF printing experience. This convenience is invaluable for resellers and creative professionals who require a simple, efficient way to produce high-quality prints.

This platform not only enhances user experience but also integrates innovative features that could redefine expectations within the industry. As technology continues to evolve, Snuggle DTF’s commitment to improving accessibility and efficiency in DTF printing could serve as a model for other companies seeking to navigate the dynamic landscape of custom garment production.

Frequently Asked Questions

What is the process of Direct-to-Film (DTF) printing?

Direct-to-Film (DTF) printing involves printing designs onto special transfer film and then applying them to fabrics using heat and pressure. This method allows for vibrant colors and intricate designs on various materials, making it popular in custom apparel printing.

How does DTF printing differ from sublimation printing?

DTF printing differs from sublimation printing primarily in its versatility. While sublimation works best on synthetic fabrics, DTF can be applied to a wider range of materials, including cotton and blended fabrics, allowing for more custom apparel printing options.

What are the advantages of using DTF transfers for custom apparel?

DTF transfers offer several advantages such as high-quality, vibrant prints, the ability to print on diverse fabric types, and cost-effectiveness for small businesses and hobbyists. They also provide an efficient process, especially with innovations in DTF printing technology.

What are gang sheets in DTF printing and why are they useful?

Gang sheets in DTF printing are designed sheets that allow multiple designs to be printed simultaneously. This method optimizes material use and streamlines the production process, making it especially beneficial for small businesses and crafters looking for efficiency.

How can I find reliable DTF printing services for my business?

To find reliable DTF printing services, consider researching companies that specialize in Direct-to-Film printing, checking reviews, and comparing service offerings and production capabilities, such as those from EazyDTF or DTFPrinter, known for their quality and efficiency.

Are there any new advancements in DTF printing technology?

Yes, there are frequent advancements in DTF printing technology, such as the introduction of large format DTF printers and custom printing services. Companies like EazyDTF are expanding their production capacity to meet growing demands, enhancing quality and turnaround times.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers are revolutionizing custom apparel printing, making it easier for DIY enthusiasts and businesses. |

| What is DTF Printing? | A printing method that transfers designs onto fabrics using a special film, offering vibrant colors on various materials. |

| EazyDTF Expansion | EazyDTF is enhancing production with new printers and same-day shipping, responding to increasing demand. |

| DTFPrinter Innovations | Introduced premium DTF and UV DTF options, improving quality and usability for custom apparel creators. |

| Snuggle DTF Platform | A new web-to-print platform making DTF more accessible for commercial trades and resellers. |

| DTF vs. Sublimation | DTF allows for vibrant prints on multiple fabric types compared to sublimation’s limitation to synthetic fabrics. |

| Understanding Gang Sheets | Gang sheets optimize material use in printing, beneficial for small businesses and individual crafters. |

Summary

DTF transfers are fundamentally changing the landscape of custom printing, offering vibrant, high-quality results that cater to a variety of fabrics. As innovations from companies like EazyDTF, DTFPrinter, and Snuggle demonstrate, the advancements in this technology have led to more accessible and efficient processes, allowing crafters and businesses to fully harness the potential of DTF printing. Understanding these changes and the advantages DTF presents over traditional methods like sublimation is crucial for anyone looking to excel in the custom apparel market. By integrating DTF into their operations, users can create unique, lasting designs that stand out in today’s competitive environment.