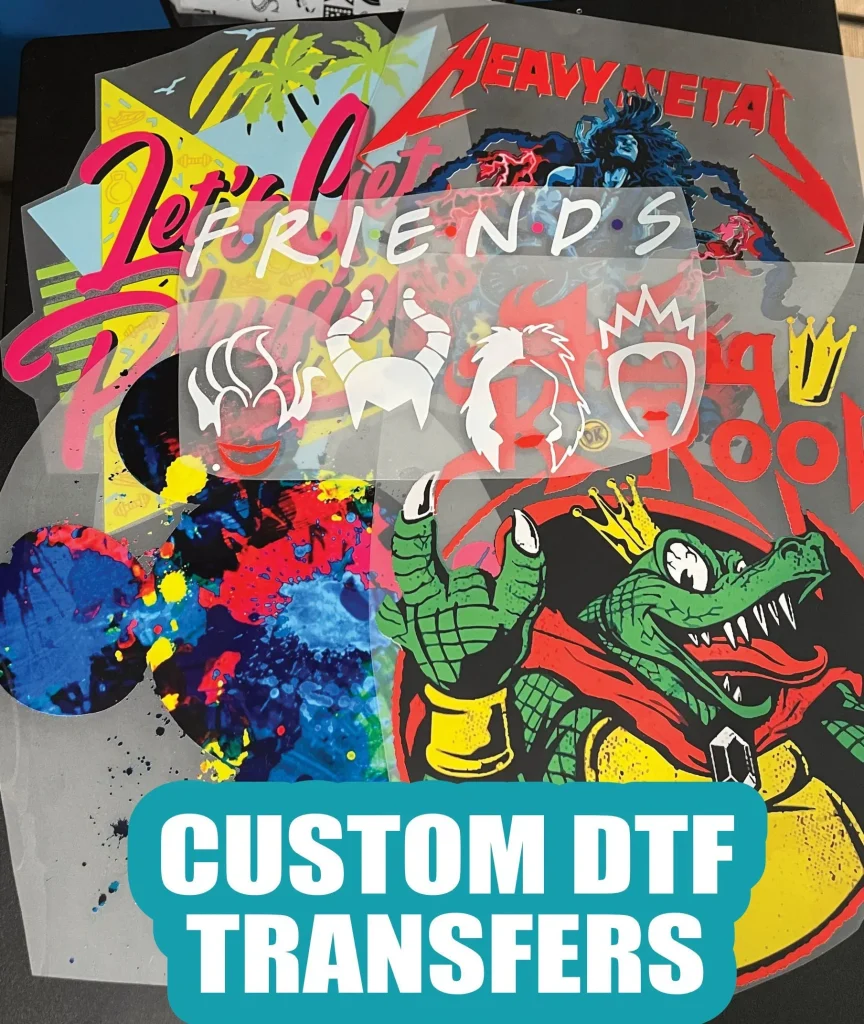

DTF Transfers, or Direct-to-Film transfers, are transforming the world of custom garment printing by providing an innovative solution that combines quality and versatility. This cutting-edge technique is quickly gaining popularity among beginners and established businesses alike, owing to its ability to deliver stunning, detailed designs on a variety of fabrics. In our comprehensive guide, you’ll discover not only how to use DTF transfers effectively but also valuable tips and tricks to make the most of this unique printing method. From the essential DTF transfer materials to the best practices for beginners, we’ll cover everything you need to know to create eye-catching custom apparel. Explore the possibilities of DTF printing as we delve into the various challenges and practical applications you might encounter along the way.

Direct-to-Film (DTF) printing stands out as a leading technique for those looking to enhance their custom apparel offerings. Often called the modern solution for garment decoration, this method employs specialized films to transfer intricate and colorful designs onto fabrics with ease. Whether’ you’re a seasoned professional or a novice seeking a beginner’s guide to DTF, understanding the core materials and processes involved is crucial for achieving vibrant, long-lasting prints. Get ready to unlock a world of creative potential with DTF transfers, as we guide you through the essentials of setting up your DTF printing project and the tips that lead to successful outputs.

Understanding DTF Printing: What You Need to Know

Direct-to-Film (DTF) printing is a revolutionary method that combines the ease of digital printing with the durability required for garment finishes. Unlike traditional methods, DTF transfers work by applying designs directly onto a special film, which is then transferred to fabric using heat and pressure. This process allows for vibrant colors and finer details to be printed, making it an appealing option for custom apparel makers. As you embark on your DTF printing journey, it’s crucial to understand the basic principles behind this technique to maximize your output quality.

Another key benefit of DTF printing is its versatility. This technique works effectively on various textiles, including cotton, polyester, and blended fabrics, making it suitable for a wide range of products, from T-shirts and hoodies to more complex apparel shapes. Understanding how DTF transfers adhere to different fabrics will allow you to select the right materials for optimal results. Furthermore, an awareness of the technology and techniques in DTF printing will enable you to innovate and experiment with new styles.

Essential Materials for DTF Transfers

To begin your DTF printing adventure, you’ll need specific materials that ensure a successful transfer. At the core of DTF printing is the DTF printer, which must be compatible with special inks and films designed for this purpose. Leading brands like Epson and Brother have established reputations for providing reliable printers that meet the demands of the DTF process. Additionally, high-quality transfer films are necessary to capture your designs accurately, ensuring they display vividly on the final apparel.

Moreover, adhesive powder is a critical component you shouldn’t overlook. This powder binds the ink to the fabric during the heat transfer phase, enhancing the print’s durability and longevity. Investing in a reliable heat press is also crucial, as it applies the necessary heat and pressure for a successful transfer. Lastly, setting up a curing station can significantly improve your workflow, allowing you to preheat prints and enhance adhesion, which is particularly beneficial when working with multiple layers or complex graphics.

Beginner’s Guide to DTF Printing

Starting with DTF printing can be both exciting and intimidating for beginners. One of the first steps is to choose the right DTF printer that matches your production goals. Look for a model that has positive user reviews and offers features such as easy setup and maintenance. Proper setup will also require familiarizing yourself with the software for artwork preparation, ensuring files are created at the right resolution for optimal quality.

Another critical step in the beginner’s journey is understanding how to prepare your artwork effectively. A common recommendation is to use high-resolution images (300 DPI or better), ensuring your designs come out crisp and clear on the final fabric. Beginners should also experiment with different fabrics to discover which textiles perform best with DTF transfers, as each material may react differently to the printing process.

DTF Transfer Tips for Successful Printing

As with any new technique, there are invaluable tips to help ensure your success with DTF transfers. One important aspect is accurate calibration of your heat press settings. The temperature and pressure must be just right; too much heat or pressure can damage the print, while too little can result in poor adhesion. Conducting tests with scrap materials before mass production can vastly improve overall quality.

Additionally, staying informed about advancements in DTF printing technology is crucial. Manufacturers frequently introduce new inks and films that can enhance durability and vibrancy. Investing time in learning about these developments can give you a competitive edge in the custom printing market and allow you to explore innovative design techniques.

Common Challenges in DTF Printing and How to Overcome Them

DTF printing comes with its share of challenges, but recognizing these hurdles can prepare you for smoother operations. One common issue is adhesion problems, often caused by incorrect settings on the heat press. It’s essential to conduct test runs and record successful settings to build a reliable reference guide as you scale up production.

Moreover, regular maintenance of your DTF printer and heat press cannot be overstated. Cleaning your equipment regularly not only enhances print quality but also minimizes costly repairs. Create a maintenance schedule to routinely check and clean your printers, ensuring they remain in top condition for all your printing needs.

Practical Applications of DTF Transfers in Custom Apparel

The versatility of DTF transfers makes them an attractive choice for a wide variety of applications in custom apparel. From T-shirts to hoodies and hats, DTF printing can accommodate intricate designs even in small production runs, a boon for small businesses and individual entrepreneurs. This allows for high-quality prints and unique designs tailored to customers’ preferences.

Moreover, DTF transfers aren’t limited to personal apparel; they’re also excellent for creating promotional merchandise. Businesses utilize DTF printing to produce branded items, enhancing visibility and creating a personal touch for events. With the ability to produce detailed graphics at an affordable cost, DTF technology opens new avenues for creativity and commercial exploration.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing method where designs are printed onto a specialized film. This film, coated with adhesive powder, is then applied to fabric using heat and pressure, resulting in vibrant and high-quality prints that adhere well to cotton, polyester, and blends.

What materials do I need for DTF printing?

To start with DTF printing, you will need a DTF printer, DTF transfer film, adhesive powder, a heat press, and possibly a curing station to preheat your prints before transferring them to fabric. Investing in quality materials is crucial for achieving good results.

How can beginners use DTF transfers effectively?

Beginners can effectively use DTF transfers by choosing the right printer, preparing high-resolution artwork, testing different fabrics, and staying updated with the latest in DTF inks and films. Conducting practice runs before full production can also help ensure quality.

What are some common DTF transfer tips for successful printing?

Some useful tips for successful DTF printing include maintaining proper temperature and pressure settings on your heat press to avoid issues like peeling, regularly cleaning your printer and equipment, and experimenting with different fabric types to understand how they interact with the transfers.

What challenges might I face with DTF transfers?

Challenges with DTF transfers may include adhesion issues if the temperature or pressure settings are incorrect, as well as the need for thorough maintenance to keep your equipment in good working condition. Testing and adjusting your settings can help mitigate these challenges.

Can DTF transfers be used for complex designs?

Yes, DTF transfers are particularly well-suited for complex designs. This method allows for intricate details and vibrant colors, making it an excellent choice for custom apparel, promotional items, and any project requiring high visual impact.

| Aspect | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs onto a specialized film that is then transferred to fabric using heat and pressure, offering vibrant colors and intricate designs on various textiles. |

| Materials Required | 1. DTF Printer (e.g., Epson, Brother) 2. Transfer Film 3. Adhesive Powder 4. Heat Press 5. Curing Station |

| Tips for Beginners | – Choose the right printer based on reviews. – Use high-resolution artwork (at least 300 DPI). – Test on different fabrics for quality. – Stay updated on new inks and films. |

| Common Challenges | – Adhesion issues due to incorrect temperature/pressure. – Importance of regular cleaning and maintenance of machines. |

| Practical Applications | – Custom apparel (T-shirts, hoodies). – Promotional items for businesses. – Complex designs for creative projects. |

Summary

DTF transfers are an innovative and accessible method for custom garment printing, ideal for those venturing into the realm of apparel design. This technique allows for vibrant, high-quality prints on various fabrics, making it an excellent choice for small businesses and hobbyists alike. By mastering the materials and tips provided in this guide, you can overcome common challenges and unlock the full potential of DTF transfers, creating stunning custom apparel that stands out in today’s competitive market.